Understanding the Role of Mini-Split AC Installers

Introduction to Mini-Split AC Systems

Mini-split AC systems have become increasingly popular due to their efficiency, flexibility, and ease of installation. Unlike traditional centralized systems, mini-splits offer a ductless solution, making them ideal for homes without existing ductwork. Their growing prevalence in both residential and commercial settings underscores the need for skilled mini-split AC installers who can ensure optimal performance and longevity.

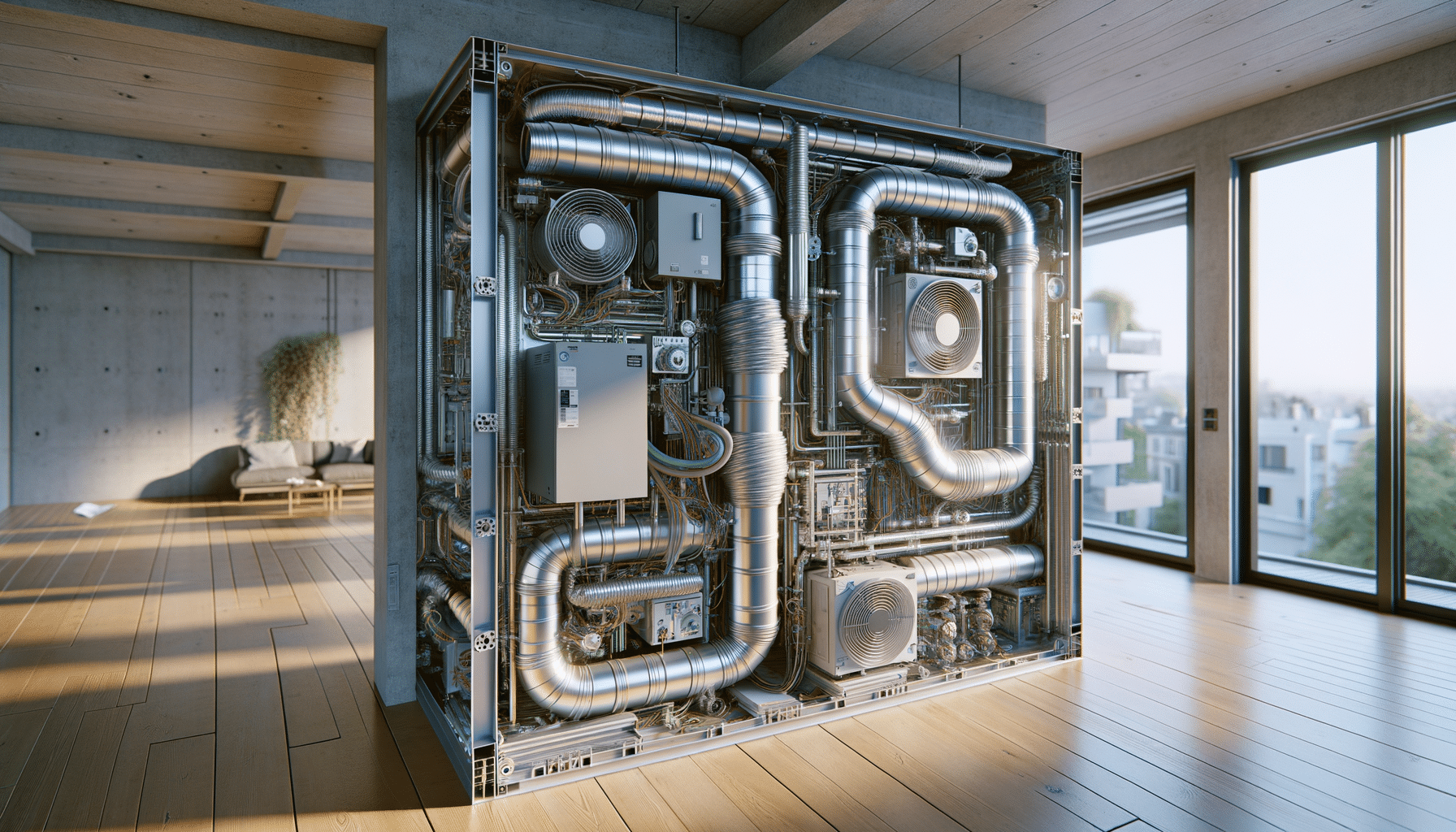

These systems consist of two main components: an outdoor compressor/condenser and an indoor air-handling unit. The installation process involves connecting these components via a conduit that houses the power cable, refrigerant tubing, and a condensate drain. This setup allows for zone-specific cooling, which can significantly enhance energy efficiency by allowing users to cool only the spaces they occupy.

Understanding the intricacies of mini-split installation is crucial for both installers and consumers. A well-installed mini-split system not only provides comfort but also contributes to energy savings and reduced utility bills. As such, mini-split AC installers play a pivotal role in ensuring that these systems are installed correctly and function efficiently.

The Expertise of Mini-Split AC Installers

The role of a mini-split AC installer is multifaceted, requiring a blend of technical knowledge, practical skills, and problem-solving abilities. Installers must assess the specific needs of each space, considering factors such as room size, insulation, and local climate conditions. This assessment is critical in selecting the appropriate system capacity and ensuring effective cooling.

Beyond initial assessments, installers must also navigate the complexities of electrical connections and refrigerant handling. Proper electrical wiring is essential for the safe operation of mini-split systems, while accurate refrigerant charging is crucial for maintaining system efficiency and longevity. Installers must adhere to industry standards and regulations to prevent issues such as refrigerant leaks, which can compromise system performance and environmental safety.

Moreover, mini-split AC installers must be adept at troubleshooting and resolving potential installation challenges. These can include finding suitable locations for the indoor and outdoor units, ensuring adequate airflow, and minimizing noise levels. A successful installation not only meets technical specifications but also aligns with the aesthetic and functional preferences of the client.

Installation Processes and Considerations

The installation process for mini-split AC systems involves several critical steps, each of which must be executed with precision. The first step is site preparation, which includes selecting appropriate locations for the indoor and outdoor units. The outdoor unit should be positioned in a well-ventilated area, away from direct sunlight and obstructions, to ensure efficient heat exchange.

Installing the indoor unit requires careful consideration of airflow patterns and aesthetic integration with the room’s design. The unit should be mounted at a height that allows for optimal air distribution, typically near the top of a wall. Installers must also ensure that the unit is level to prevent condensate drainage issues.

Once the units are positioned, the installer must connect them using the conduit. This involves drilling a small hole through the wall to pass the conduit, which contains the power cable, refrigerant lines, and drain hose. The installer must then vacuum the refrigerant lines to remove air and moisture, a step that is crucial for preventing system inefficiencies and damage.

Enhancing Energy Efficiency

One of the primary benefits of mini-split AC systems is their potential for enhanced energy efficiency. By allowing for zone-specific cooling, these systems reduce the energy wasted on cooling unoccupied spaces. This targeted approach can lead to substantial energy savings and lower utility bills.

To maximize energy efficiency, mini-split AC installers must ensure that the system is properly sized for the space. An undersized system may struggle to cool the area effectively, while an oversized system can cycle on and off too frequently, leading to energy waste and increased wear and tear.

Additionally, installers can advise clients on best practices for using their mini-split systems efficiently. This includes setting appropriate temperature levels, maintaining regular maintenance schedules, and utilizing programmable timers or smart controls to optimize usage patterns. By empowering clients with this knowledge, installers contribute to long-term energy savings and system sustainability.

Common Challenges and Solutions

Despite their advantages, mini-split AC systems can present certain challenges during installation. One common issue is finding suitable locations for the outdoor unit, especially in densely populated urban areas with limited space. Installers must be creative in identifying locations that provide adequate ventilation and minimize noise disturbance.

Another challenge is ensuring proper refrigerant line installation. Leaks or improper connections can lead to reduced system efficiency and environmental harm. Installers must be meticulous in checking for leaks and ensuring that all connections are secure and compliant with regulations.

Finally, installers may encounter challenges related to electrical wiring and power supply. Ensuring that the electrical system can support the mini-split’s power requirements is essential for safe operation. Installers must work closely with clients to address any electrical upgrades or modifications needed to accommodate the system.

By anticipating and addressing these challenges, mini-split AC installers can ensure successful installations that deliver comfort, efficiency, and reliability.