Understanding the Process of EV Charger Installation

Introduction and Outline: Why EV Charger Installation Matters Now

Electric mobility is moving from early adoption to everyday practicality, and charger installation sits at the center of that shift. Whether you are a homeowner planning a garage upgrade, a property manager evaluating amenities, or a fleet operator eyeing operating cost stability, a well-planned installation can be the hinge between smooth daily operations and frustrating bottlenecks. The process is rarely only about plugging in new hardware; it is about understanding how energy flows, how charging behavior unfolds over time, and how sites are engineered for safety, resilience, and cost control. Done thoughtfully, charger installation becomes a long-term investment that supports drivers, balances grid demand, and enhances property value.

To set clear expectations, here is the roadmap this article follows, including both strategy and hands-on considerations:

– Infrastructure backbone: service capacity, grid readiness, load management, and future-proofing

– Charging stations: AC vs. DC, power levels, siting, accessibility, and operations

– Electric vehicles: batteries, onboard chargers, real-world charging behavior, and compatibility

– Installation process: assessment, permitting, construction, commissioning, and maintenance

– Conclusion: targeted next steps for homeowners, property owners, and fleet managers

The goal is to demystify jargon and provide a structured approach. We will compare power levels and dwell times, weigh installation trade-offs, and translate technical terms into decisions you can act on. For context, average daily driving in many regions hovers around 30–40 miles, which often aligns with overnight charging at home or regular top-ups at work. Meanwhile, workplaces, retail hubs, and depots benefit from a mix of charging speeds that match typical stay durations, minimizing cost while improving availability. As you read, imagine your own use case—garage, curbside, lot, or depot—and keep an eye on the long arc: what you install today should be flexible enough to support tomorrow’s vehicles without constant rework.

The Infrastructure Backbone: Power, Panels, and Planning for Growth

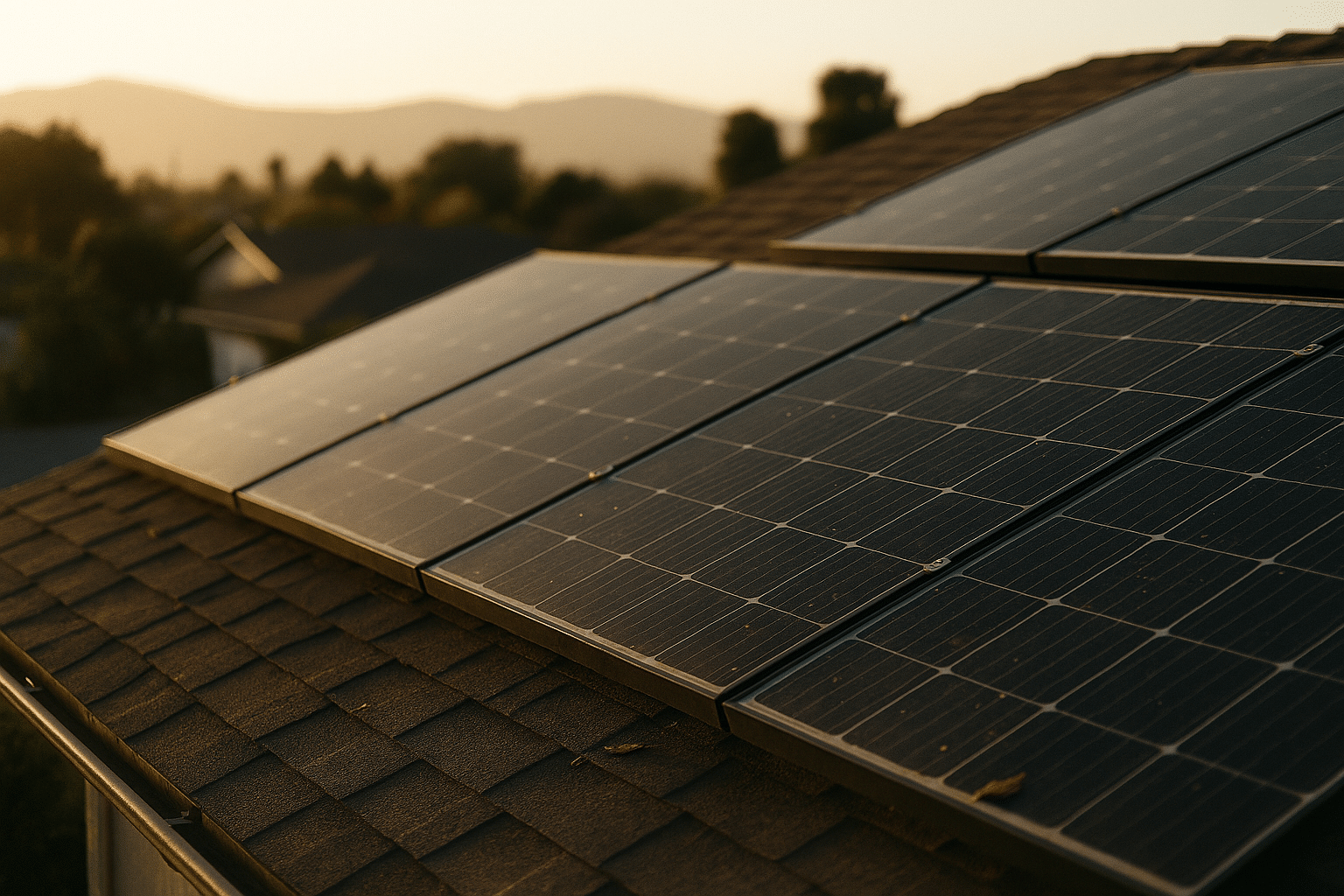

Every charger installation starts with a simple question: how much power do you have, and how much do you need? That answer is grounded in your service capacity, utility constraints, and the electrical panel that feeds your property. Residential services commonly range from 100 to 200 amps, and a typical AC Level 2 charger (around 7–11 kW) can draw 30–50 amps on a dedicated circuit. In multifamily, commercial, or fleet settings, multiple chargers compound the load, and the conversation quickly includes transformer capacity, feeder sizing, conduit routes, and space for expansion. For high-power DC charging, three-phase service is often essential, and on some sites, utility upgrades can become the pacing factor for the entire project timeline.

Costs and grid impacts can be managed with smart planning. Load management allows multiple charging ports to share a defined power budget, prioritizing vehicles based on arrival time, state of charge, or schedules. Time-of-use rates and demand charges, where applicable, can influence operating costs more than hardware pricing. Strategies such as scheduled charging, peak-shaving with energy storage, or pairing with on-site generation can smooth peaks and protect budgets. Reliability also belongs in the infrastructure conversation: redundancy in circuits, clear labeling, robust grounding, and surge protection all help achieve high uptime, which drivers notice immediately.

To structure your infrastructure review, consider this short checklist:

– Service and panel: existing amperage, breaker availability, and code-compliant room to expand

– Utility coordination: metering options, potential upgrades, timelines, and incentives

– Site layout: cable runs, trenching paths, accessibility, and vehicle circulation

– Environmental factors: temperature swings, precipitation, corrosion risk, and enclosure ratings

– Monitoring and data: metering for reimbursement, dashboards for uptime, and basic alerts

A forward-looking design is not just a nice-to-have; it reduces rework. Conduit oversizing and spare pull strings are inexpensive now and priceless later. Accessible junction points, labeled panels, and well-documented as-built drawings shorten maintenance windows and minimize downtime. If your site might eventually host faster chargers or additional stalls, leaving physical space and electrical capacity pathways in the initial build can transform future upgrades from major overhauls into simple additions. In short, the infrastructure backbone is the quiet hero of every successful installation.

Charging Stations: Types, Power Levels, Siting, and Operations

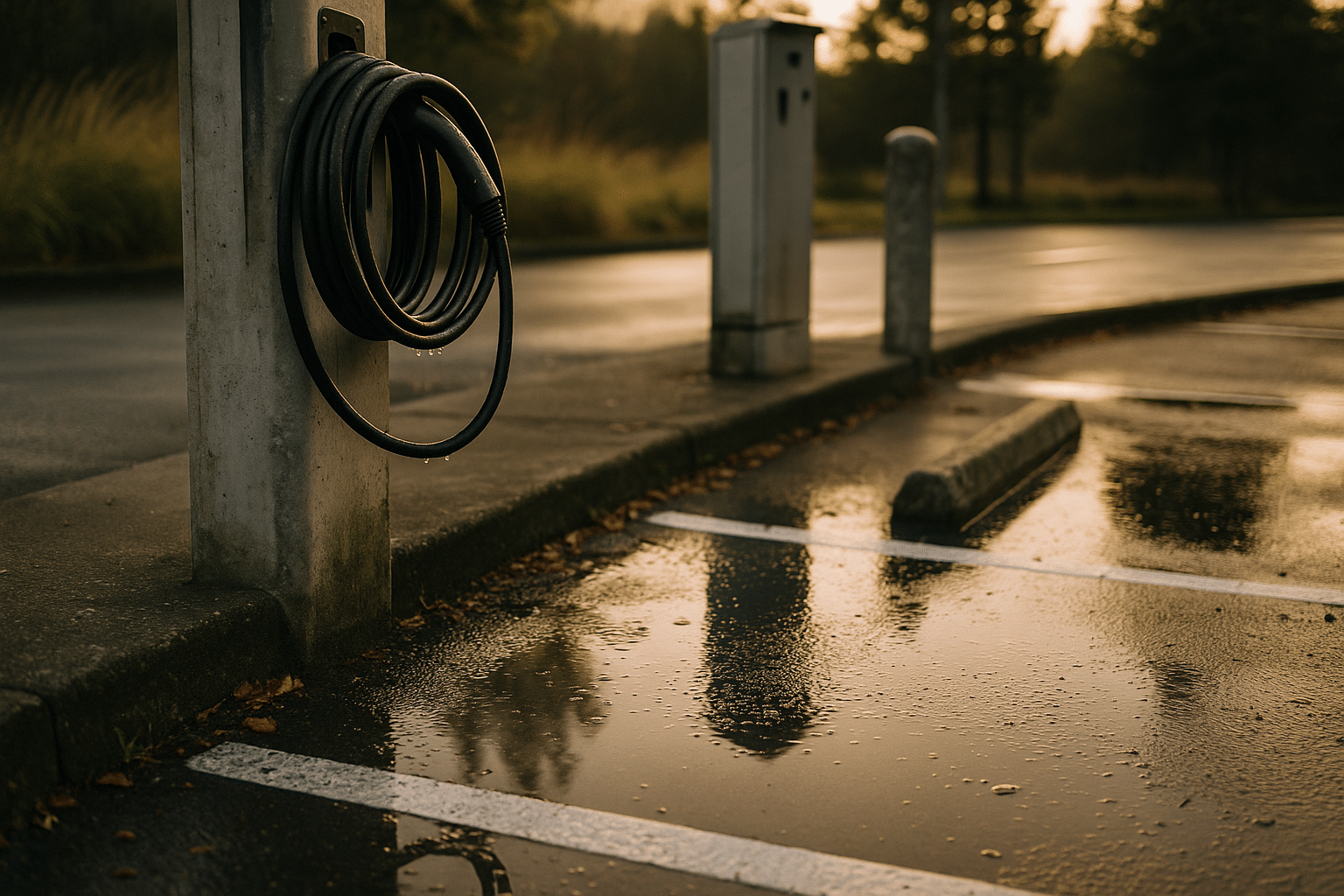

Charging stations fall into two broad families: AC and DC. AC Level 1 relies on standard outlets and adds modest range per hour, suitable for overnight stays or low-mileage use. AC Level 2 typically provides 7–19 kW, enough to add dozens of miles in a few hours—ideal for homes, workplaces, and public destinations where drivers park for longer. DC fast charging ranges roughly from 50 to 350 kW and targets quick turnarounds, common along highways or at logistics hubs. The right mix depends on dwell time: the longer vehicles stay parked, the more AC charging makes economic and operational sense.

Siting decisions shape driver experience and operating costs. Place stations where vehicles naturally pause: near building entrances for accessibility, at the perimeter for fleet circulation, or centrally for shared parking. Consider cable reach and parking orientation to avoid awkward back-ins or blocked spaces. Visibility encourages use, while weather protection and thoughtful lighting support safety. For public sites, payment options and clear pricing build trust; networked stations enable usage tracking, remote diagnostics, and simple firmware updates. For private sites, access controls and user groups help manage who charges and when.

When comparing station features, weigh more than power ratings:

– Electrical profile: adjustable current limits, load sharing, and reliable ground fault protection

– Enclosure and durability: weather-resistant housings, cable strain relief, and vandal-resistance

– Accessibility: mounting heights, clearances, and intuitive status indicators

– Data and control: open protocols, simple dashboards, and exportable usage data

– Serviceability: modular components, replaceable cables, and easy-to-source parts

Operations and maintenance deserve early attention. Plan periodic inspections for cable wear, connector cleanliness, and signage visibility. Keep spare parts for high-use sites, and document procedures for resets and fault clearing. Many operators target uptime north of 97% by combining preventive maintenance with responsive support processes. Finally, evaluate total cost of ownership: hardware, installation, software, electricity, maintenance, and, where relevant, networking fees. A station that is simple to maintain and easy to use often delivers stronger long-term value than a higher-powered unit deployed in the wrong context.

EV Requirements and the Installation Roadmap: From Car Needs to Commissioning

Before anyone runs conduit, start with the vehicle. Battery sizes frequently span 40–100 kWh, and onboard AC chargers often accept 6–11 kW, which sets the practical ceiling for home and workplace AC charging speeds. DC charging capability varies, with some vehicles peaking near 100–150 kW and others reaching higher; real-world rates depend on temperature, state of charge, and the vehicle’s charging curve. Drivers who plug in daily can thrive with AC Level 2, while corridor travel and fleet duty cycles often justify at least some DC coverage. Seasonal conditions matter too: cold weather can slow charging unless the battery is warmed, and preconditioning can improve both speed and efficiency.

With vehicle needs defined, the installation roadmap comes into focus:

– Site assessment: document panel capacity, breaker space, grounding, and cable routes

– Load calculation: account for existing appliances and set safe, code-compliant margins

– Design and permitting: select locations, mounting methods, and apply with the authority having jurisdiction

– Utility coordination: confirm service sufficiency, metering plans, and potential upgrades

– Construction: trenching or surface raceways, conduit, wire pulls, mounting, and protective bollards

– Electrical work: dedicated circuits, appropriate wire gauge, overcurrent protection, and labeling

– Commissioning: torque checks, insulation testing, verification of ground fault protection, and software setup

– Driver experience: wayfinding, stall markings, and simple instructions

A few practical tips elevate outcomes. For homes, consider a dedicated 40–60 amp circuit for flexibility and use a licensed electrician familiar with local code. In multifamily or workplaces, plan shared power with dynamic load management so additional ports can be added without rebuilding service. Where trenching is involved, lay spare conduit for future runs; the marginal cost today is far less than digging again. For DC projects, allow space for power cabinets, clear airflow, and safe vehicle maneuvering. Document everything—panel schedules, cable routes, network settings—so maintenance is fast and predictable. Finally, schedule a brief handoff: walk users through safe connector handling, secure cable storage, and basic troubleshooting, building confidence from day one.

Conclusion and Next Steps: A Clear Path for Homeowners, Property Owners, and Fleets

Successful EV charger installation blends thoughtful planning with practical execution. Homeowners benefit from right-sizing an AC circuit, placing the charger where cable reach is effortless, and leveraging off-peak schedules to save money. Property owners strengthen tenant satisfaction and attract visitors by matching charging speed to typical stay length, prioritizing accessibility, and investing in monitoring for uptime. Fleet managers gain predictable operations by analyzing routes and dwell windows, balancing AC for routine parking with targeted DC capacity for quick turns.

Consider this concise action list as you move forward:

– Define your use case: daily miles, dwell times, and how many vehicles need to charge at once

– Check infrastructure: service capacity, panel room, and pathways for expansion

– Choose station types: AC for longer stays, DC where quick turnarounds are essential

– Plan operations: pricing, access control, maintenance cadence, and simple user guidance

– Future-proof: spare conduit, modular hardware, and open data pathways

The transition to electric mobility rewards early clarity. Start with the vehicle needs, design the infrastructure to support them, and select stations that fit the way people actually park. Pair that with a clean commissioning process and a light-touch maintenance plan, and you will deliver reliable charging that feels natural to use. The destination is not just a powered-up stall; it is a system that supports drivers without drama, adapts to growth, and keeps energy costs and downtime under control. With a steady plan, the maze simplifies into a route you can follow with confidence.