Understanding the Benefits of Storm Window Replacement

Outline

– Introduction: Why storm window replacement matters for comfort, costs, and conservation

– Types and materials: Interior vs. exterior, frame choices, glazing options, performance metrics

– Installation: Measuring, sealing, moisture control, safety, DIY vs. professional approaches

– Energy efficiency and costs: U-factor, SHGC, air leakage, climate strategies, payback examples

– Maintenance and conclusion: Longevity, cleaning, condensation management, sustainability, decision guide

Why Storm Window Replacement Matters: Comfort, Efficiency, and Practicality

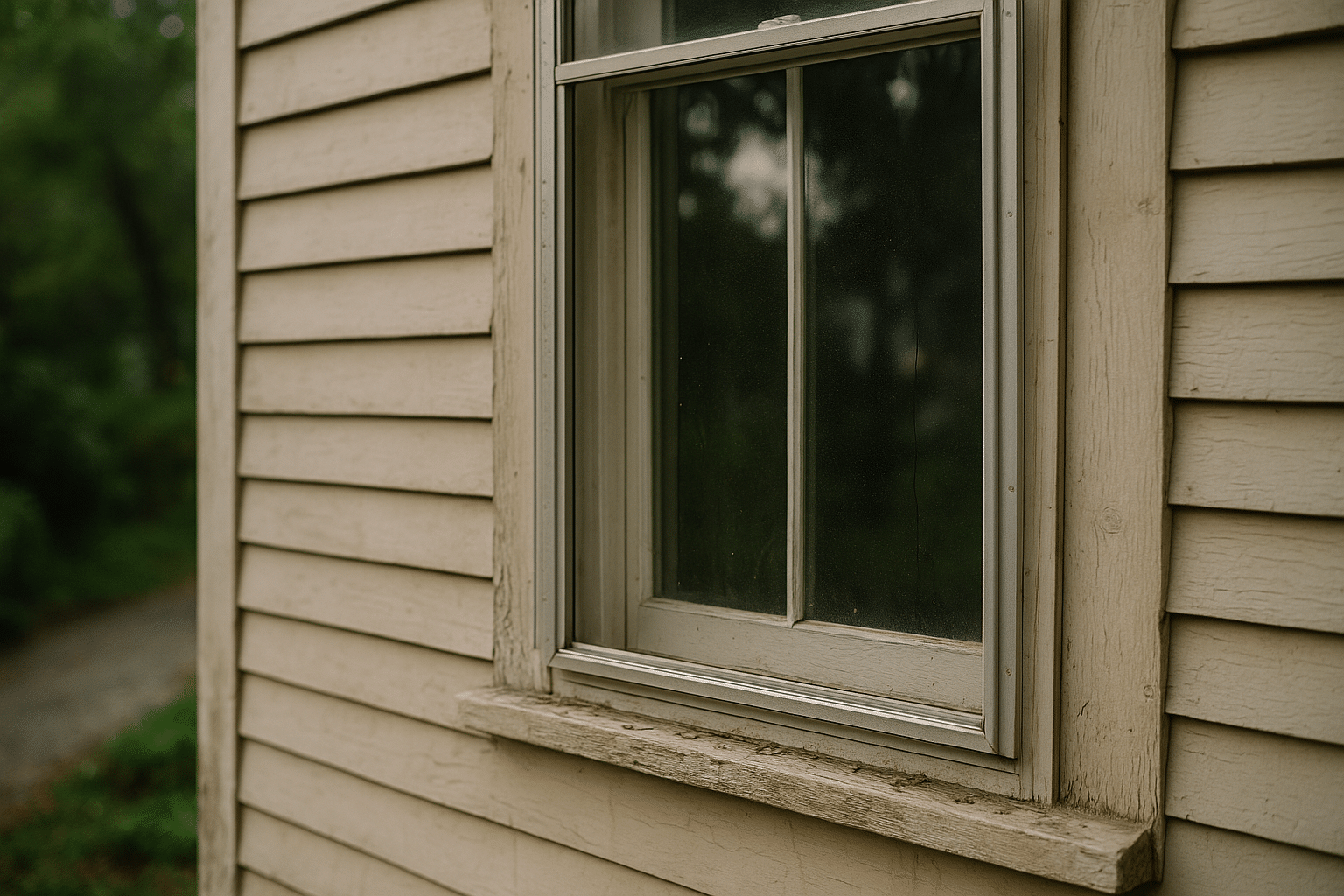

Storm window replacement is often overlooked because it feels less glamorous than full-frame window swaps. Yet, in many homes—especially older or historic structures—adding or upgrading storm windows delivers notable comfort gains and measurable energy savings without disrupting interior trim or exterior character. A well-fitted storm window creates a secondary air barrier and insulating layer, curbing drafts that sabotage your heating and cooling. Compared with full window replacement, a storm unit can be less costly, less invasive, and surprisingly effective when paired with a reasonably sound primary window.

Comfort shows up first. Residents notice fewer cold spots near glass in winter and reduced radiant heat on sunny days. The added pane and sealed air space can quiet traffic noise and temper hot or cold blasts that otherwise slip through gaps and sash joints. For renters and homeowners alike, those incremental improvements translate to rooms that feel more consistent from wall to wall. In climates with windy winters, storm windows help block infiltration, lowering the workload on furnaces. In humid summers, they can lessen indoor heat gain and reduce the runtime of air conditioners. That synergy—lower infiltration plus moderated heat transfer—explains why field studies have found meaningful energy reductions with quality storms, including low-emissivity (low-e) options.

Durability and preservation matter too. Many older houses have solid wood primary windows that still operate well but leak air. Replacing them outright may be expensive, difficult, or undesirable for aesthetic or historical reasons. Modern storms can integrate with existing frames, maintain curb appeal, and protect primary sashes from weathering. For owners facing budget constraints, phased replacement starting with the draftiest exposures (often north- and west-facing in cold climates, or sun-baked elevations in hot regions) can deliver early wins without stretching finances. Meanwhile, the lower embodied carbon of upgrading storms versus discarding serviceable primary windows appeals to eco-conscious renovators seeking impact without excess waste.

In short, storm window replacement sits at a practical intersection: comfort upgrades, credible efficiency gains, preservation of character, and an attainable price point. It is not a cure-all for every building issue—insulation and air sealing elsewhere still matter—but it is a strong lever that transforms the experience of a room with a relatively modest intervention.

Types, Materials, and Performance: Choosing the Right Storm Windows

The right storm window starts with configuration. Interior storms mount on the room side, creating a discrete air space between the new panel and the existing sash. Exterior storms mount on the outside, defending the primary window from wind, rain, and UV exposure. Selection depends on priorities such as weather protection, ease of removal, and historic guidelines. Interior units excel in fast installation and minimal exterior visual change, while exterior units may provide added durability against the elements.

Frame materials influence weight, rigidity, and maintenance. Common choices include:

– Aluminum: slim profiles, stable in varied temperatures, typically low maintenance

– Vinyl: solid insulating value in the frame, good corrosion resistance, easier cleaning

– Wood: classic look, can blend with historic trim, requires more upkeep to resist moisture

Glazing decisions carry major performance implications. Clear glass is the traditional option, offering durability and scratch resistance. Acrylic or polycarbonate panels are lighter and impact-resistant but can scratch more easily. Low-e glass includes a microscopically thin coating that reflects infrared energy while allowing visible light through, enhancing winter heat retention and de-emphasizing radiant heat gain on sunny days. In many climates, low-e storms offer a balanced approach to reducing heating and cooling loads without overly dimming natural light.

Track design affects usability. Double- or triple-track exterior storms allow sashes and screens to move independently for ventilation. Interior storms often use compression fit, magnetic seals, or discreet clips to form a tight perimeter seal with quick seasonal removal. Whatever the design, airtightness is crucial. Look for features that reduce air leakage at the frame-to-opening interface and at panel seams. A snug fit plus compressible weatherstripping minimizes the bypass paths that quietly erode efficiency.

Performance metrics help compare options. While storms may not always carry the same labeled metrics as full window units, many provide data or third-party testing to indicate expected U-factor reductions and air leakage improvements. You can also evaluate glazing specifications: low-e coatings typically shift the solar heat gain coefficient (SHGC) downward, aiding cooling-dominant climates, while lower overall U-factors help in heating-dominant regions. A practical rule: select glazing that aligns with your climate and orientation—higher solar control for south- and west-facing exposures in hot regions; stronger insulation emphasis for north-facing windows in cold regions.

Finally, aesthetics and maintenance deserve attention. Consider sightlines, color matches, and trim profiles to ensure your storm windows look integrated rather than tacked on. Think ahead about cleaning access, screen swapping, and off-season storage for removable panels. A well-chosen system should feel natural in day-to-day use, sturdy in a storm, and discreet when the sun sets and indoor lights glow.

Installation Essentials: Measuring, Air Sealing, and Moisture Management

Even exceptional storm windows cannot perform if they are poorly installed. Accurate measurement is the foundation, especially in older homes where openings may be out of square. Measure width and height in multiple places and use the smallest dimension to avoid an oversize panel that will not seat properly. Note sill angles, casing irregularities, and any proud trim that could impede a flush fit. For exterior storms, locate existing weep paths or plan new ones to allow incidental moisture to escape.

The basic installation flow generally includes:

– Prepare the opening: clean surfaces, remove old caulk or debris, and repair rotten spots

– Dry-fit the unit: check reveals, verify that corners align, confirm latch clearance

– Seal judiciously: apply continuous beads near the perimeter but do not block weep routes

– Fasten correctly: use corrosion-resistant screws appropriate for the substrate

– Verify operation: open and close sashes or remove interior panels to confirm smooth use

Air sealing is a balancing act. You want a continuous seal between the storm frame and the existing window frame, but you must not trap water where it can cause deterioration. For exterior storms, installers often leave tiny, intentional weep gaps at the bottom or rely on integrated weep holes in the frame. Use compatible sealants—often a high-quality elastomeric or silicone—while avoiding excessive application that can dam water. Indoors, compression-fit interior storms benefit from even pressure along all edges; a slight bow or uneven reveal can create a leak path that undermines performance.

Thermal expansion and contraction deserve respect. Dark frames in sunlit exposures can expand noticeably, so leave manufacturer-recommended clearances to prevent binding. Where shims are needed, space them carefully and avoid creating point loads that twist the frame. For masonry openings, pre-drilling and using anchors sized for the substrate helps maintain alignment over time.

Safety and health considerations are essential. In homes built before the late 1970s, disturbed paint may contain lead; follow safe work practices and consider professional help when paint is loose or chipping. Use proper eye and respiratory protection when scraping, sanding, or drilling. If you are unsure about structural issues around the opening, consult a qualified pro—storm windows cannot compensate for rot-riddled sills or failing headers.

DIY versus professional installation depends on your comfort with precise measurements, sealant control, and ladder work. A careful DIYer can achieve a solid result on straightforward openings, especially with interior storms. Complex, tall, or uneven elevations often justify professional involvement, which can minimize callbacks and protect against moisture-related mistakes. Prioritize quality over speed; a meticulous afternoon can mean years of quieter, cozier evenings.

Energy Efficiency and Cost: What the Numbers Say

To understand the value of storm window replacement, it helps to translate features into performance metrics and dollars. Three concepts dominate: U-factor (overall heat transfer), SHGC (how much solar heat passes through), and air leakage (infiltration). Lower U-factor reduces heat loss in winter and heat gain in summer. Lower SHGC blocks more solar heat, valuable in hot, sunny climates. Lower air leakage directly reduces drafts and HVAC runtime, often delivering comfort that exceeds what the raw numbers suggest.

Typical outcomes vary by climate and building condition, but studies on low-e storm windows have reported heating energy savings on the order of single-digit to mid-teen percentages in cold regions and cooling energy reductions of similar magnitude in warm regions. Older, leaky primary windows can see larger gains because the baseline is inefficient. When storms are installed tightly, infiltration can drop meaningfully, reducing temperature swings near windows and allowing thermostats to cycle less frequently.

Consider a simplified example. Suppose a home with 15 aging windows faces high winter bills. Upgrading to low-e storms at a moderate cost per unit may yield annual savings that produce a simple payback in a modest number of years. That payback can shrink further when utility rebates or weatherization programs are available. The non-energy dividends—comfort, noise reduction, and protection of primary windows—do not show up on a bill, but they carry real value and often tip the decision from “maybe later” to “let’s schedule it.”

Cost drivers include:

– Frame material and glazing: low-e coatings raise price but often improve savings

– Custom sizing and color: precise fits and matched finishes increase labor and material costs

– Installation complexity: height, access, and substrate conditions influence labor time

– Additional air sealing: addressing surrounding trim or gaps may add to the budget but boost results

Comparing storms to full window replacement clarifies the strategic role of storms. A full replacement can deliver lower U-factors and integrated labeling, but at a significantly higher upfront cost, plus potential disruption to finishes. In many scenarios, storms paired with serviceable primary windows capture a large share of the comfort and energy benefits at a fraction of the price. For owners planning phased upgrades, storms can serve as an immediate improvement while deferring a major replacement to a future capital cycle.

Finally, think beyond utility bills. The embodied energy and materials of discarding a functional primary window are not trivial. Installing storms extends the life of existing assemblies, reducing waste and preserving original character where that matters. When a smaller investment achieves notable reductions in energy use and a clear bump in day-to-day comfort, the holistic return often looks compelling.

Maintenance, Durability, and Conclusion: Getting Long-Term Value

Like any building component that moves, seals, and sheds water, storm windows reward light, regular care. Clean glass and frames with mild soap, and avoid abrasives on soft glazing materials such as acrylic. Check weatherstripping at least once a year; compressible seals can wear, especially on frequently operated sashes. Inspect exterior storms after big storms for clogged weep holes or wind-driven debris. Inside, ensure compression-fit panels still seat evenly after seasonal humidity swings.

Common issues and simple responses include:

– Condensation between primary and storm: improve the seal, verify weeps, and manage indoor humidity

– Rattling or whistling: tighten fasteners gently and add thin weatherstripping where gaps persist

– Sticky tracks: clean grit from channels and apply a light, appropriate lubricant to reduce friction

– Scratched acrylic: use a plastic polish kit; for severe damage, consider glazing replacement

Longevity emerges from good installation and routine maintenance. Quality frames resist corrosion, and low-e coatings are engineered for years of service under normal use. Exterior storms shield the primary window from rain and sun, slowing paint failure and reducing sash swelling. Interior storms minimize dust infiltration and protect delicate finishes. Together, they form a system where each component helps the other last longer.

From a sustainability perspective, storm windows punch above their weight. They cut energy waste, preserve existing materials, and are often recyclable at end of life, depending on the frame and glazing. For households watching cash flow, they allow targeted investments: start with rooms you use most or elevations with the strongest sun or wind exposure, then expand. For owners of historic homes, storms align with preservation goals by maintaining original profiles while discreetly upgrading performance.

Conclusion for homeowners, landlords, and facility stewards: if your primary windows are structurally sound but drafty, storm window replacement offers a well-regarded path to better comfort and efficiency without a full-scale renovation. Focus on airtightness, appropriate glazing for your climate, and careful installation that respects moisture movement. Maintain seals, keep weeps clear, and reassess fit every season. With those habits, storm windows become a quiet partner in daily comfort—holding heat when the mercury drops, easing the load when the sun beats down, and protecting the windows that give your building its character.