Solar Panels Explained: How They Work, Types, Efficiency, and Maintenance Tips

Outline:

– How solar panels work and why they matter

– Types of solar panels and where each fits

– Efficiency and real-world performance

– Installation and maintenance tips

– Costs, incentives, and a practical decision framework

Introduction and How Solar Panels Work: From Sunlight to Usable Power

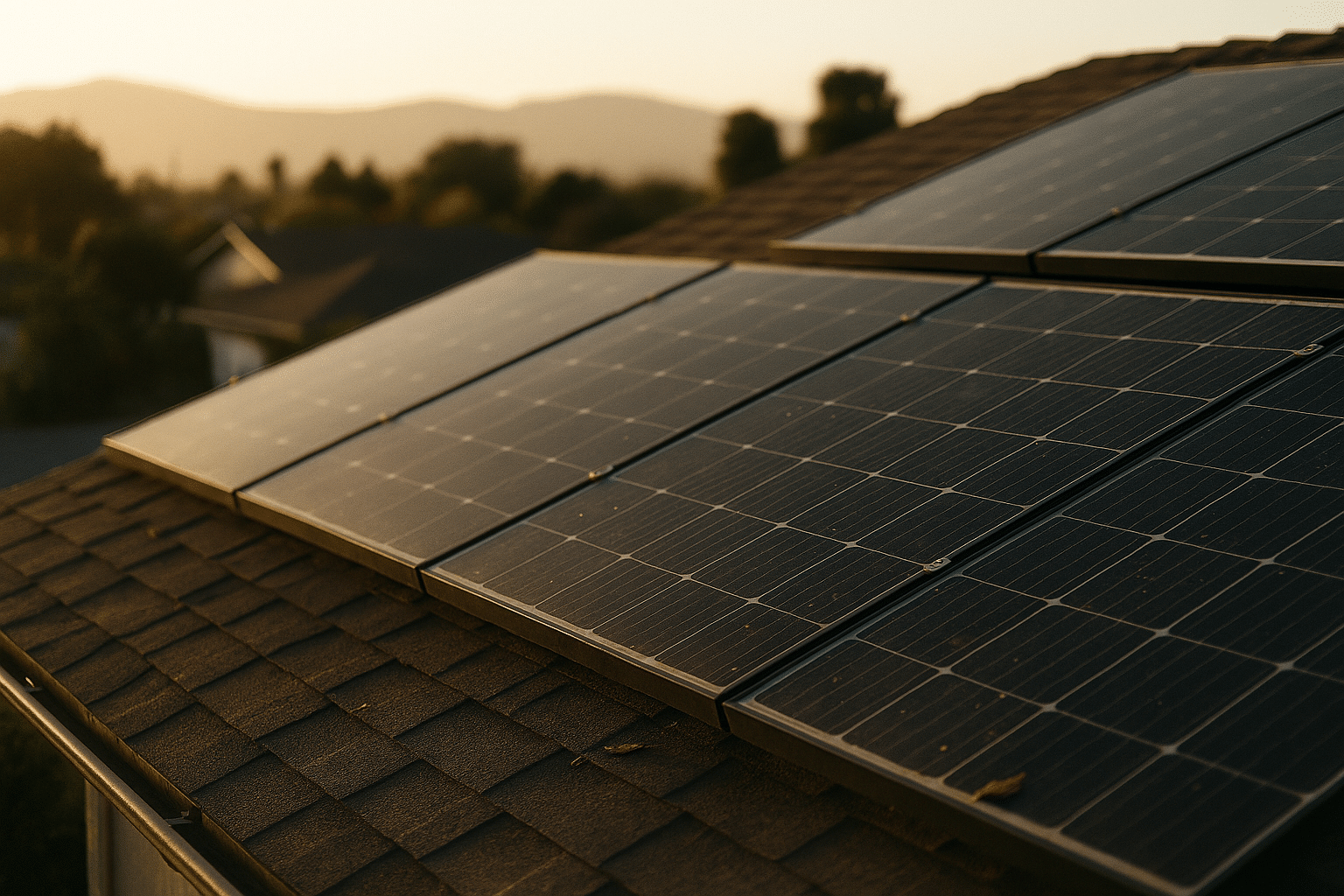

Imagine a rooftop as a quiet, tireless messenger turning sunlight into useful electricity. That’s the essence of solar panels: devices that convert light into direct current through the photovoltaic effect. Most modules use silicon wafers forming a p-n junction. When photons strike the semiconductor, electrons gain energy and move, creating an electric field–driven flow. Conductive busbars collect this current, which leaves the module as DC. An inverter then converts DC to AC, aligning with household and grid standards. Modern systems add safety devices (rapid shutdown components, fuses), monitoring hardware, and racking that secures modules against wind and weather.

At a system level, the anatomy typically includes: modules wired in series/parallel, racking and flashing to protect the roof, DC disconnects and combiner boxes, inverters (string, micro, or power-optimizer architectures), grounding and rapid-shutdown features, and production monitoring. Each choice affects performance and resilience. For example, module-level power electronics can mitigate shading losses by controlling each panel independently, while string inverters can be simpler and cost-effective for unshaded roofs. Bypass diodes within modules help current flow around shaded cells, reducing hot spots and power collapse.

Why does this matter? Distributed solar reduces line losses, bolsters grid resilience, and displaces high-emission generation. Life‑cycle analyses generally estimate photovoltaic electricity at roughly 20–50 g CO2‑e per kWh, far lower than conventional fossil sources, even after accounting for manufacturing and end-of-life handling. Durability is another draw: mainstream panels are designed for decades of service, with typical linear warranties and observed degradation often around 0.3–0.8% per year. Meanwhile, module costs have fallen dramatically over the past decade, widening access for households, farms, and small businesses. In short, solar is a practical tool for lowering bills, hedging against energy price swings, and shrinking one’s footprint—all by harvesting a resource that arrives every morning.

Panel Types Compared: Monocrystalline, Polycrystalline, Thin-Film, and Specialty Options

Not all solar panels look or perform the same, and the differences matter when you’re matching technology to your roof, climate, and goals. Monocrystalline modules, easily recognized by their deep, uniform color, are known for higher efficiency—often in the high teens to low twenties—thanks to a single-crystal structure that improves electron mobility. They typically deliver more watts per square meter, which helps on tight roofs. Polycrystalline modules, with their speckled appearance, usually land a bit lower in efficiency, often mid- to high‑teens, yet they can offer strong value where space is plentiful and budgets are tighter. Thin‑film technologies (such as amorphous silicon or other semiconductor compounds) trade peak efficiency for light weight, flexible form factors, and sometimes superior low‑light or high‑temperature performance.

Beyond these mainstream categories, specialty options are expanding what solar can look like. Bifacial modules capture light from both sides, boosting yield over reflective surfaces like light-colored roofs or ground cover. Building‑integrated photovoltaics hide generation in shingles, skylights, or facades; while aesthetically appealing, they can carry higher costs and lower efficiencies. Flexible laminates are useful for curved surfaces or weight‑sensitive structures, though they demand careful attention to mounting and cooling to avoid thermal buildup.

Choosing among types starts with context. Consider the following quick cues:

– Limited roof area: prioritize higher‑efficiency monocrystalline modules.

– Harsh heat or partial shading: evaluate bifacial modules or designs with module‑level power electronics.

– Weight constraints or unique surfaces: look at thin‑film or flexible formats with appropriate fire and wind ratings.

– Visual design requirements: consider building‑integrated options but verify output and cost trade‑offs.

Climate also shapes the decision. In hot regions, temperature coefficients (often around −0.3% to −0.5% per °C above 25°C) become important—lower magnitude coefficients lose less power on scorching days. In snowy climates, robust frames, higher ground clearance, and slicker glass can help shedding. In coastal areas, corrosion‑resistant hardware and tested salt‑mist ratings are worth scrutiny. Ultimately, any “top-rated” pick depends on site realities: roof geometry, shade from trees or neighboring structures, local codes, and the balance between upfront cost, aesthetics, and long‑term yield.

Efficiency, Performance, and Real-World Yield: What Numbers Actually Mean

Panel efficiency tells you how much sunlight becomes DC electricity under standard test conditions (1,000 W/m², 25°C cell temperature, AM 1.5 spectrum). It’s a helpful benchmark, but real rooftops are messier. Cell temperatures often exceed 25°C, cutting output by the temperature coefficient. Airborne dust, pollen, or salt spray can dampen production until rain or cleaning removes it. Wiring and inverter losses, mismatch among modules, and brief shading (chimneys, vents, trees) all add up. As a result, overall system performance is better described by the performance ratio (PR), which aggregates these effects; many well‑designed systems achieve PR values around 0.75–0.85 over a year.

Energy yield, measured in kWh, depends on local solar resource and array design. Orientation and tilt matter: in the northern hemisphere, south‑facing arrays at a tilt near local latitude generally perform well, though roofs dictate compromises. East‑west layouts can spread production across the day, sometimes aligning better with household usage. Annual production per kilowatt of DC capacity commonly ranges from roughly 1,000–1,800 kWh/kW depending on latitude, weather patterns, and shading, with sunnier regions near the upper end. Degradation is gradual; after 20 years, many arrays still generate the majority of their initial output.

Several practical tactics improve yield:

– Find and minimize partial shading; even small obstructions at key hours can create outsized losses.

– Right‑size the DC/AC ratio; mild inverter “clipping” at noon may be acceptable if it boosts morning/afternoon harvest and overall economics.

– Keep conductors, connectors, and fuses correctly sized and torqued to reduce resistive losses and heat.

– Monitor performance; small anomalies caught early prevent long‑term energy loss.

– Plan for soiling; in dusty zones, yields can drop several percent between rains, and brief seasonal cleanings may pay off.

Finally, a note on ratings. Standard tests are comparable, but your roof never sees a laboratory day. Look at temperature behavior, low‑light response, and shading mitigation holistically, and judge the system on annual kWh, not just nameplate watts. The winning setup is the one that reliably meets your energy goals in your climate with minimal fuss.

Installation and Maintenance Tips: Designing for Safety, Longevity, and Low Hassle

Good solar begins with a thorough site assessment. Confirm roof age and structure, verify that rafters can handle the added load, and locate optimal array zones free from midday shade. Pay attention to roof penetrations: flashed mounts installed to manufacturer specifications preserve waterproofing, while correct standoff height supports airflow and cooling. On ground mounts, consider frost depth, soil conditions, and wind exposure. Electrical design requires proper conductor sizing, overcurrent protection, equipment grounding, and code‑compliant rapid shutdown. Clear labeling, accessible disconnects, and tidy wire management simplify future service and keep animals from nesting under arrays.

Maintenance is mostly light but intentional. Modern glass is durable and hydrophobic coatings help, yet soiling still accumulates differently by region. In many temperate climates, rain does most of the cleaning; in arid or agricultural zones, a gentle rinse during dry seasons can restore a few percent of output. Avoid abrasive brushes and hard water that can leave mineral spots; use soft water or squeegees where available. Annual visual inspections catch loose clamps, cracked conduit fittings, or UV‑aged cable ties. Thermal cameras can spot hot cells or failing diodes, while a quick look at monitoring data will reveal string outages or sagging production well before a bill hints at trouble.

Safety deserves top billing:

– De‑energize per procedures before service; DC arcs are persistent.

– Use fall protection on pitched roofs and respect anchor points.

– Keep clearances around combiner boxes and inverters for ventilation and access.

– Verify torque on mechanical fasteners; thermal cycling can loosen hardware over time.

– Confirm that rapid‑shutdown and grounding continuity tests pass after any changes.

Weather resilience is baked into certification testing, which includes hail impact, thermal cycling, and damp heat. Still, local conditions vary; if hail is common, seek modules with robust glass and frames and pair them with well‑anchored racking. For coastal sites, components with verified salt‑mist ratings and stainless fasteners reduce corrosion risk. At end of life, responsible recycling programs can recover glass, aluminum, and some semiconductor material. With thoughtful design and a light maintenance rhythm, arrays deliver decades of quiet service, letting you forget they exist—until the utility bill arrives with a grin‑worthy total.

Costs, Incentives, and a Practical Decision Framework: Bringing It All Together

Solar economics blend hardware, labor, permitting, and policy. Installed prices vary widely by country and market maturity, but residential systems commonly fall within a few dollars per watt (pre‑incentive). Financing shapes outcomes: paying cash can yield the strongest lifetime savings; loans spread costs but add interest; leases and power‑purchase agreements may reduce upfront expense while ceding some benefits. Incentives—such as tax credits, rebates, or performance‑based payments—shorten payback. Net‑metering or export tariffs determine how excess energy is valued, and those rules sometimes change, so checking current policies is essential.

A simple example illustrates the math. Suppose a 6 kW system priced at $2.50/W totals $15,000 before incentives. If local sun yields about 1,350 kWh per kW each year, annual production is roughly 8,100 kWh. At an electricity rate of $0.18/kWh, that offsets about $1,458 annually. Add in a hypothetical 20% incentive and the net cost drops to $12,000, nudging simple payback toward 8–9 years, with decades of continued operation beyond that. Actual numbers will hinge on your rates, usage patterns, and policies, but this framework shows how to analyze offers side by side. Storage can add resilience during outages; it also adds cost and introduces round‑trip efficiency losses (often 5–15%), so weigh autonomy against economics.

Use this decision checklist:

– Roof fit: Is there enough unshaded area to meet your kWh goals?

– Structural health: Will the roof last 20+ years, or is replacement due first?

– Tariffs: How are exports credited and are rates time‑of‑use?

– Incentives: Which programs apply now, and what are their deadlines?

– Monitoring: Will you have clear, module‑level or system‑level performance visibility?

– Future loads: Are you planning heat pumps or an EV that could change sizing?

Conclusion: Solar rewards those who pair clear goals with site‑appropriate design. If you value predictable energy costs, quieter environmental impact, and gear that mostly minds its own business, a thoughtfully planned array is among the most compelling home upgrades available. Start with a shade analysis and a few quotes that detail equipment, warranties, expected kWh, and assumptions about utility rates. Compare proposals using annual energy, not just nameplate watts, and favor transparent documentation. With that, you’ll be well‑equipped to choose a highly rated system that fits your roof, your budget, and your long‑term plans.