Essential Considerations for a Successful Bathroom Remodel

Outline

– Renovation Roadmap: scope, budget, timeline, and risk planning

– Hidden Essentials: plumbing, waterproofing, and ventilation fundamentals

– Choosing Fixtures: performance metrics, efficiency, and finishes

– Tiles and Surfaces: material science, safety ratings, and installation

– Execution: DIY vs pro decisions, quality control, and long-term maintenance

Renovation Roadmap: Scope, Budget, and Timeline

A successful bathroom remodel starts by translating ideas into measurable goals. Define the room’s purpose, the users, and the constraints before you touch a tile. Is this a compact powder room focused on quick refreshes, or a primary bath designed for daily, spa-like routines? Clarifying use uncovers required features: a curbless shower for accessibility, two sinks for shared schedules, or storage tailored to cosmetics and linens. From there, capture the scope in a written brief that lists nonnegotiables, nice-to-haves, and items to defer if costs rise.

Turn the brief into a realistic budget by separating labor, materials, and contingency. Labor commonly accounts for 40–60% of cost, materials for 30–50%, and a 10–15% reserve cushions surprises like hidden moisture or outdated wiring. Price ranges vary by region and finish level, but planning by line item—demolition, framing, plumbing, electrical, waterproofing, tile, fixtures, ventilation, paint—prevents drift. Time is the second currency: a modest cosmetic refresh might take 1–2 weeks, while a full gut with layout changes, inspections, and custom tile work can stretch to 4–8 weeks.

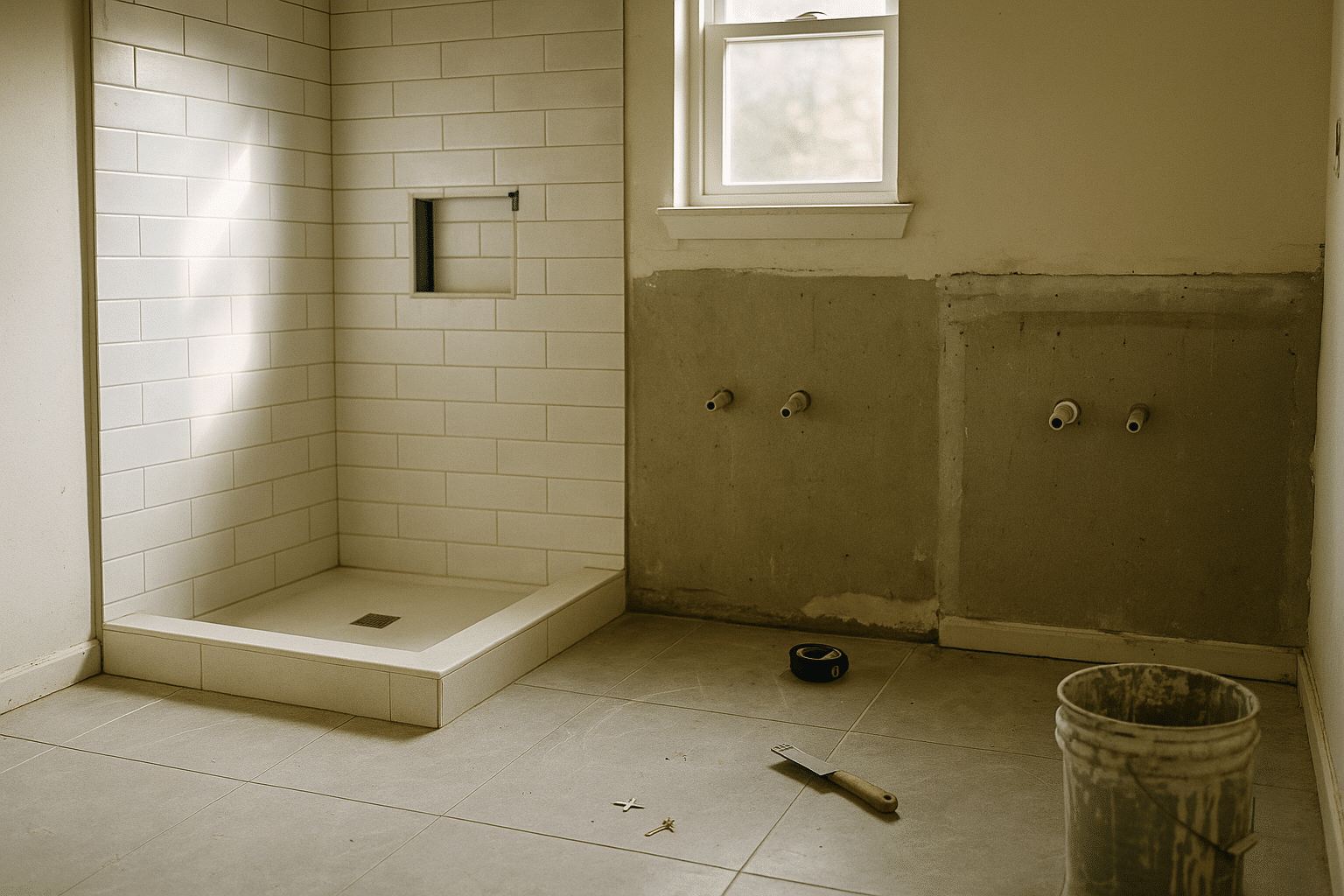

You’ll also want a schedule that sequences tasks to avoid rework. Typical order: demolition, rough plumbing and electrical, inspections, wall repair and floor prep, waterproofing, tile, fixtures, lighting, paint, and final caulking. Each step has dependencies—tile can’t start before waterproofing cures, and vanities should not be installed before floor tile is set and grouted. A written timeline with milestones reduces delays, especially when special-order items need weeks to arrive.

Risk planning pays off when walls open. Old valves, undersized vents, or uneven subfloors are common. Reserve time for corrections and specify decision points in advance. A simple checklist keeps the project grounded:

– Confirm all materials are on site before demolition

– Photograph rough-in locations for future reference

– Verify slope and waterproofing with a flood test before tiling

– Approve tile layout and grout color with a dry run

By aligning scope, budget, and calendar—and anticipating detours—you’ll steer the project with calm, not guesswork.

Hidden Essentials: Plumbing, Waterproofing, and Ventilation

The beauty of a finished bathroom hides a network of systems that keep water where it belongs. Start with plumbing: supply lines should deliver stable pressure, ideally between 40–60 psi, to prevent drips and ensure steady temperature control. Drains need proper sizing and slope; a 2-inch drain for showers is common, with a 1/4 inch per foot slope guiding water to the trap without pooling. Where multiple fixtures share lines, thoughtful routing reduces noise and pressure changes when another tap opens across the hall.

Shower valves are your safety anchor. Pressure-balancing valves help maintain temperature when pressure fluctuates, while thermostatic valves allow you to set an exact temperature—both limit scald risk. Pay attention to fixture height and reach: place controls at a comfortable 38–48 inches above the floor and within easy reach from outside the spray so you don’t step into cold water. For accessibility, consider a handheld shower on a sliding bar and a bench that fits the user’s seated height and knee clearance.

Waterproofing is more than tile; it’s a system. Cement board or an appropriate backer provides the base, but the waterproofing layer does the heavy lifting. Sheet membranes create a continuous barrier with seams lapped correctly, while liquid-applied membranes form a monolithic film when applied to specified thickness. In wet zones—showers, niches, benches, curbs—continuity is critical. Corners and penetrations are the weak spots; preformed corners and gaskets around valves and showerheads reduce risk. A 24-hour flood test of shower pans before tile is a practical safeguard, catching pinholes and imperfect seams early.

Ventilation protects the investment you’re building. Fans are sized by airflow: a common rule is about 1 CFM per square foot of bathroom floor area, with higher capacity for enclosed showers or long duct runs. Noise matters; lower sone ratings encourage regular use. Ducts should run short and straight, insulated in unconditioned spaces, and exhaust outdoors—never into an attic. Pair the fan with a timer or humidity sensor and run it for 20–30 minutes after a shower to keep relative humidity near or below 50%. Add passive measures too: a small undercut at the door improves airflow, and a window can provide natural venting when weather allows. These quiet choices—right-sized drains, continuous waterproofing, and effective ventilation—prevent problems that don’t announce themselves until repairs get costly.

Quick checks before closing walls:

– Verify drain slope and trap locations with photos and measurements

– Confirm waterproofing thickness and complete coverage at corners

– Test fan airflow at the exterior cap for strong discharge

– Label shutoffs and valve orientations for future service

When the hidden details are correct, the visible finishes last longer and perform as intended.

Choosing Fixtures: Performance, Efficiency, and Longevity

Fixtures set the daily feel of a bathroom, from the first splash at dawn to the last rinse at night. Start with faucets: look for flow rates around 1.2–1.5 gallons per minute for sinks to conserve water without compromising usability. Ceramic disc cartridges have become standard for durability and smooth control. Spout reach should comfortably clear the sink basin to reduce splash, and lever handles are easier for small hands or arthritic grips. Finishes like chrome, brushed nickel, and matte options each have their quirks—polished surfaces can show water spots, while brushed textures hide fingerprints and minor scratches.

Showers reward careful planning. A single fixed head at 1.8–2.5 gpm can deliver a pleasant spray if the head design matches your pressure. Handheld units add flexibility for rinsing and cleaning, especially when paired with a slide bar that doubles as a grab point when properly reinforced. Decide between pressure-balancing and thermostatic control; thermostatic setups offer more precise temperature stability, useful in households with varying demands. Consider a recessed niche sized for large bottles and placed out of the main spray to reduce soap scum buildup.

Toilets combine efficiency and comfort in more ways than a quick spec sheet reveals. Modern gravity-fed models commonly use 1.28 gallons per flush, and a well-designed trapway can clear with fewer double flushes. Bowl shape impacts experience: elongated bowls improve ergonomics in tighter footprints with minimal space penalty, while comfort heights around 17–19 inches ease standing and sitting for many adults. A fully glazed trapway and quality flapper or canister seal reduce maintenance, and quiet-close seats avoid nighttime surprises.

Sinks and tubs round out the suite. Undermount and integral sinks simplify cleanup at the counter edge. For materials, vitreous china resists staining, while cast iron offers heft and sound dampening at the expense of weight. Acrylic tubs hold heat well and are easier to install; steel can be durable but transmits sound unless insulated. Drain placements matter: a centered drain can be comfortable in a soaking tub, while an end drain maximizes lounging space.

Don’t forget the support cast:

– Aerators and laminar flow devices influence splash and clarity

– Angle stops with quarter-turn valves simplify future repairs

– Supply lines with braided stainless sleeves resist kinks

– Trap adapters with cleanouts make maintenance faster

By measuring performance (gpm, gpf), checking ergonomics, and selecting finishes that match real cleaning habits, you’ll assemble fixtures that feel cohesive and last beyond trends.

Tiles and Surfaces: Materials, Ratings, and Installation

Tile is both skin and armor for a bathroom, creating mood while standing guard against water. Ceramic and porcelain are the workhorses. Ceramic is typically easier to cut and adequate for walls and low-traffic floors, while porcelain, with water absorption often under 0.5%, brings extra density and durability—valuable for floors and wet zones. Natural stone adds character through unique veining and color variation, but usually needs sealing and more attentive care. Large-format tiles can visually expand a small room, yet they demand a very flat substrate to avoid lippage.

Safety and durability are quantifiable. Check the dynamic coefficient of friction (DCOF) for wet areas; tiles with a DCOF of 0.42 or higher are commonly recommended for interior floors exposed to water. For wear, a PEI rating guides resistance to abrasion on glazed tiles—higher ratings suit heavier traffic. Edge types affect layout: rectified edges enable tight joints and crisp lines, while pressed edges soften transitions and may better disguise minor irregularities. In showers, mosaic sheets (2 inches or smaller) on floors conform to slope and offer more grout lines for grip.

Substrate and waterproofing determine longevity. Cement backer boards or appropriate foam boards provide dimensionally stable surfaces, while uncoupling membranes help manage movement and prevent cracked grout lines. Plan expansion and movement joints at changes in plane—where wall meets floor, in inside corners, and around the perimeter. Use flexible sealant in these joints rather than rigid grout. In showers, a pre-slope under a pan liner or an integrated bonded membrane system directs water efficiently to the drain, avoiding stagnant moisture.

Grout choice influences maintenance. Cementitious grout is budget-friendly and workable but benefits from sealing; epoxy grout resists stains and water ingress with minimal maintenance and suits high-use showers; urethane and hybrid formulations provide stain resistance with easier installation than traditional epoxy. Color selection matters: mid-tones hide minor staining better than bright whites or very dark hues. Sealing stone and grout (where applicable) helps repel stains, but follow manufacturer intervals to avoid over-application and haze.

Practical installation notes:

– Aim for substrate flatness within 1/8 inch over 10 feet for large-format tile

– Dry-lay patterns to balance cuts at walls and avoid slivers

– Maintain consistent grout joint width with spacers suitable for tile size

– Back-butter large tiles to enhance coverage; target at least 95% in wet areas

– Use a high-quality wet saw for clean edges and reduced chipping

With the right material science and methodical prep, tile becomes a durable canvas that handles splashes, steam, and the test of time.

Execution: DIY vs Pro, Quality Control, and Maintenance

Every remodel begins as a sketch and ends as a space you live in; execution is the bridge between intent and outcome. Decide early which tasks you’ll self-perform and which you’ll hire out. Many homeowners handle demolition, painting, and simple hardware installation, while licensed professionals tackle rough plumbing, electrical, and complex waterproofing. The dividing line is risk: errors behind walls are expensive to fix later. If hiring, collect multiple written bids with the same scope so comparisons are meaningful. Ask about licensing, insurance, scheduling capacity, and workmanship warranties, then confirm references by viewing similar completed projects.

Contracts should detail the scope, milestones, payment schedule, and processes for change orders. A material schedule naming quantities, finishes, and model specifications prevents substitutions that don’t match. Before work begins, stage materials and verify counts—tile square footage with overage, grout color, valve trim components, and rough-in kits. Label boxes by room and wall to speed installation, and store items in a dry, temperate area to avoid warping or finish damage.

Quality control is a daily habit. Check that shower pans pass a flood test, confirm wall studs are plumb before backer board goes up, and verify tile layout centers on focal points like niches or mirrors. Use a long straightedge to catch waves in walls and floors, and inspect grout joints for uniformity. Photograph rough-ins and final assemblies for your records; the images will save time years later when you need to locate a stud or valve. At the end, perform a punch walk: run water at every fixture, test drains, flip switches, open and close doors, and examine caulk lines and paint edges under bright light.

When the dust settles, maintenance protects your investment. Squeegee shower walls and doors after use to reduce mineral buildup and mildew. Keep relative humidity near 50% with a reliable fan and occasional window ventilation. Clean with pH-neutral products to safeguard grout and natural stone; avoid harsh abrasives that scratch finishes. Re-caulk wet joints annually or when cracking appears, and inspect toilet supply lines and shutoffs for seepage. A quarterly checklist is simple insurance:

– Run and time the exhaust fan to ensure strong airflow

– Inspect grout and sealers; spot-reseal high-use areas as needed

– Check under-sink traps for drips and tighten compression nuts gently

– Clear weep holes in shower drains to maintain flow

With steady attention and thoughtful choices, your bathroom will age gracefully—less a showpiece on day one, more a reliable companion year after year.