Understanding the Process of Sump Pump Replacement

Outline:

– Introduction to sump pump replacement and why timing matters

– Installation: planning, safety, and step-by-step replacement

– Submersible sump pumps explained, with comparisons to pedestal designs

– Maintenance routines that extend life and improve reliability

– Sizing, costs, backup options, and code considerations

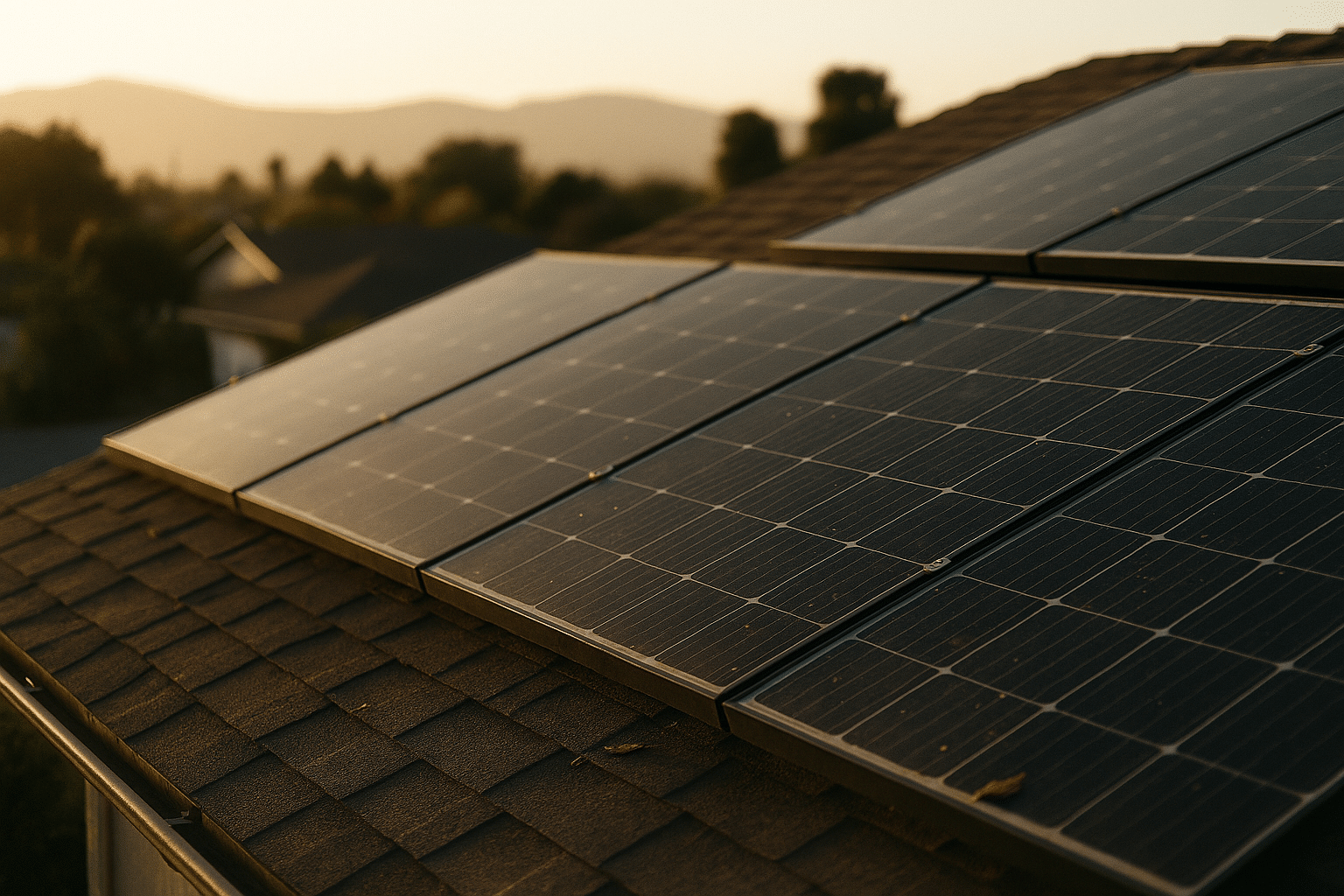

Introduction: Why Sump Pump Replacement Matters

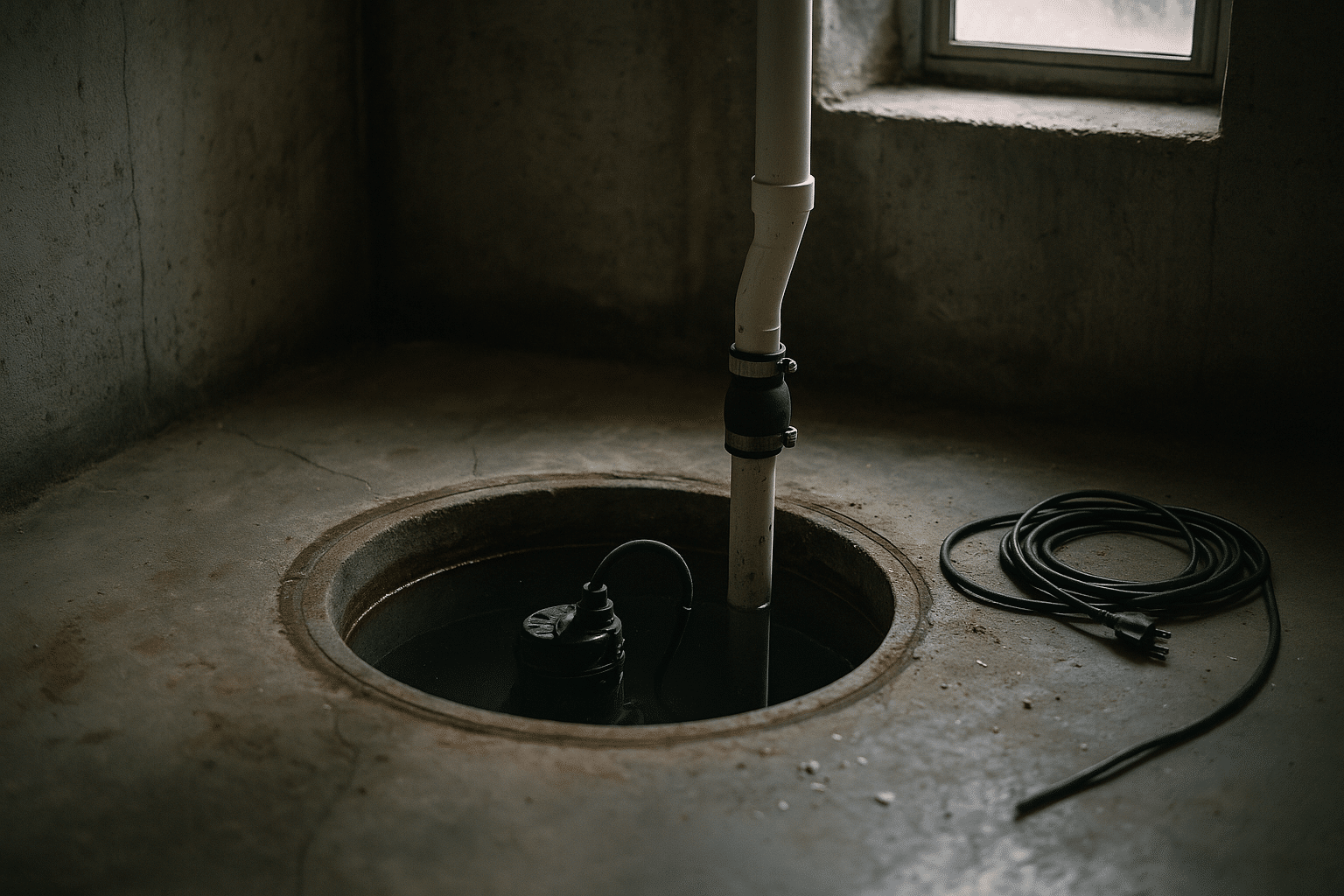

Basement water problems don’t send calendar invites; they arrive with the next storm or snowmelt. A sump pump is the quiet guardian that shuttles groundwater away from your foundation, and replacing it before failure can mean the difference between a routine chore and a weekend of remediation. A helpful way to grasp the stakes: one inch of water spread across a 1,000‑square‑foot basement equals roughly 623 gallons. That’s about 83 cubic feet of water, and if a pump fails when runoff spikes, the inflow can overwhelm even modest floor drains. The typical residential sump pump lasts around 7–10 years depending on runtime, water chemistry, and maintenance. If your pump is approaching that age, running noisier, or short-cycling, planning a replacement on your terms is smart risk management.

Two common pump categories serve most homes: pedestal and submersible. Pedestal units keep the motor above the pit, making them easy to service and workable in narrow basins. Submersible units sit underwater with a sealed motor, operating quietly and handling higher flows for many installations. Either style can do the job when sized correctly, but replacement is an opportunity to right-size, improve the discharge path, and add backup power or alarms. Consider that heavy rain events can produce sustained inflows for hours; building in headroom gives you margin.

Beyond preventing water damage to finishes, a reliable pump protects indoor air quality by limiting moisture that feeds mold. It also preserves the integrity of structural materials like sill plates and floor joists. Practical upgrades often cost less than repairing a soaked carpet and drywall. This article walks through installation steps, digs into submersible pump details, outlines maintenance that actually moves the reliability needle, and finishes with sizing, costs, and code notes. Along the way you’ll find examples, simple math for head height and capacity, and small tweaks—like air‑relief holes and check valves—that pay off when the weather is loudest.

Installation: Planning, Safety, and Step-by-Step Replacement

The cleanest sump pump replacement starts with a plan. Before buying anything, map your system: measure the pit diameter and depth, note the vertical rise to the discharge point, and trace the horizontal run to where water exits outdoors. This total “dynamic head” largely determines which horsepower and flow rating you need. Many homes run well with 1/3 to 1/2 horsepower units, typically moving about 30–60 gallons per minute at roughly 10 feet of head, but your actual requirement hinges on local groundwater behavior and plumbing layout. Turn off power at the breaker, and if the old pump sits in standing water, unplug at a ground‑fault protected outlet once you can reach safely.

Lay out parts and tools before you touch fittings. Working methodically reduces surprises when you’re elbow‑deep in a pit. Helpful items include:

– Pump with appropriate voltage, float style, and capacity

– PVC discharge pipe (often 1 1/2 inches), couplings, primer, and cement

– Check valve sized to the pipe, ideally with a union for quick service

– Pipe cutter or saw, tape measure, level, and drill with a small bit for an air‑relief hole

– Silicone or rubber grommet for the sump cover and a tight cord pass‑through

Remove the old pump by loosening the coupling below the existing check valve. Inspect the check valve; if it’s older or shows wear, replace it while the line is open. Clean debris and sediment from the pit, and look for signs of silt intrusion—fine grit accelerates wear. Dry-fit the discharge riser so the pump sits level on the basin floor. Drill a tiny air‑relief hole—about 1/8 to 3/16 inch—on the vertical discharge section a few inches above the pump outlet and below the check valve. This prevents air locking, a common cause of a motor spinning without moving water.

Glue the PVC joints per solvent instructions, keeping the pipe straight to minimize friction losses. Mount the check valve with the flow arrow pointing up. Route the discharge to daylight at least several feet from the foundation on a downslope; avoid directing water toward a neighbor’s property or onto walkways where freezing occurs. Where permitted, some areas allow connection to a storm line using a backwater device—sanitary sewer hookups are typically prohibited. Connect power to a dedicated, grounded, and ground‑fault protected receptacle. Run a test cycle by slowly filling the pit with water and watching the float travel, switch action, and discharge. Observe for leaks and backflow chatter when the pump stops; a gentle “thunk” at shutoff is normal, but repeated rattling may indicate a misaligned or undersized valve.

Final touches include a snug pit cover to limit odors, vapor, and stray debris; clear labeling of the breaker; and, if you choose, quick‑connect fittings that simplify future pump swaps. If you add a battery backup pump, route its discharge independently or with a Y‑fitting and dedicated check valve so the systems don’t fight each other. A careful install day sets you up for years of quiet, predictable operation.

Submersible Sump Pumps: Inner Workings, Pros and Cons, and Comparisons

Submersible sump pumps live underwater by design. The motor is sealed within a watertight housing, and cooling occurs through the surrounding water—an efficient heat sink during long cycles. Most use either a vertical float, tethered float, or an internal pressure switch to trigger operation. The impeller draws water through screened inlets, pushes it into the volute, and out through the discharge. Because the entire unit resides in the pit, noise is dampened by water and a sealed cover, making submersibles a strong choice when bedrooms or living areas sit near the mechanical space.

Compared to pedestal designs, submersibles bring several practical advantages. They generally support higher flow at a given horsepower and handle small solids better thanks to larger intake area and impeller geometry. Their low profile helps in wider basins and reduces the risk of the unit tipping if the float nudges an obstruction. With the motor submerged, vibration and sound are harder to perceive—a benefit in finished basements. On the tradeoff side, submersible motors live in a harsher environment; over many seasons, mineral deposits, silt, and heat cycling can shorten life. When they fail, you typically remove the whole unit for service, whereas pedestal motors are more accessible above the lid.

When choosing between the two, match the choice to your constraints rather than chasing a trend. If your pit is narrow (e.g., under 12–14 inches), a pedestal may physically fit better. If the basement is a living space and quiet is a priority, submersible units are often preferred. Consider float type too: tethered floats need more lateral room but are simple; vertical floats use a guide rod and fit tight spaces; pressure switches reduce moving parts but may be more sensitive to debris. For corrosion resistance, housings of cast iron or stainless components resist heat deformation and dissipate warmth better than thin composites, which can help during extended run events.

Performance comparisons should anchor on head curves rather than horsepower labels. A model rated for, say, 50 gallons per minute at 10 feet may deliver far less at 18 feet with long, narrow piping and several elbows. Look up the flow at your estimated dynamic head and give yourself margin for storm surges. If your inflow calculations suggest 35 gallons per minute during peak rain, selecting a submersible that delivers 50 gallons per minute at your true head provides breathing room. Add a quiet check valve and a covered pit, and a submersible can blend into the background while moving a surprising amount of water.

Maintenance: Routine Care, Testing, and Lifespan Management

Routine maintenance turns a sump pump from a “maybe” into a dependable appliance. Start with a simple monthly check during wet seasons: look into the basin, clear loose debris, and run a test cycle by pouring water into the pit. Watch the float’s full travel and ensure the pump shuts off a few seconds after the water drops below the intake. Confirm that water exits where intended outdoors, not into a saturated garden bed or a spot that slopes back toward the foundation. Listen for grinding or squealing, which can indicate worn bearings or an obstruction. Note any musty odor from a stagnant pit; a covered basin helps, and occasional cleaning prevents organic buildup.

Seasonal care pays dividends. In spring and fall, power down at the breaker and lift the pump for a closer look. Sediment tends to settle into low areas; scooping out silt and gravel removes the abrasive grit that accelerates wear. Inspect the float and guide rod for slime that can cause sticking. Verify that the air‑relief hole is clear—use a small wire to clean it. Examine the check valve’s orientation and seals; a valve that leaks can add thousands of extra start‑stop cycles over a year, shortening motor life. If your discharge runs above grade outdoors, attach a removable extension for icy months and store it when freezing ends. A few maintenance moments can lengthen service life by years.

Documenting maintenance helps catch patterns. Keep a simple log:

– Date, weather, and whether the pump cycled during inspection

– Observed noises, smells, or odd behavior

– Any cleaning performed and parts replaced

– Battery backup test results and voltage readings if applicable

Annual tasks provide a deeper reset. Replace brittle gaskets, refresh pipe insulation near cold exterior walls, and pressure‑wash the inside of the discharge extension if algae forms. Test power resiliency by simulating an outage; a battery backup or water‑powered unit should take over within seconds. Smart water alarms or float sensors can send alerts when the water level rises unexpectedly; even a simple audible alarm is far better than discovering a problem after a storm. Finally, consider proactive replacement when the unit reaches the far side of its expected lifespan or after repeated alarms. Preventive swaps are far less stressful—and usually cheaper—than emergency calls during a heavy downpour.

Sizing, Costs, Backup Power, and Code Considerations

Right-sizing a replacement begins with estimating inflow and head. Head height is straightforward: measure vertical rise from the pump outlet to the highest point of the discharge line, add the remaining rise to the exit, and include friction losses for fittings. A quick rule of thumb adds roughly a foot of head for every 10 feet of horizontal run and for each sharp elbow, though actual loss varies with pipe size and flow. To approximate inflow, time how long the pump runs and rests during a storm. If a 40‑gallon pit fills every two minutes and empties in 30 seconds, you’re seeing about 20 gallons per minute of inflow. Choose a pump that can exceed this rate at your calculated head, leaving safety margin for heavier events.

Cost varies by region and complexity, but you can plan ranges. Material costs include the pump, PVC, check valve, solvent, fittings, and a sealed cover. Labor time increases with cement drilling for a new discharge, long runs, or upgrades like a dedicated circuit. Typical homeowner projects fall somewhere between modest DIY expenses and professional services that include warranty and disposal. Life‑cycle cost matters more than sticker price: a durable, efficient unit that reduces runtime and maintenance can cost less over a decade than a bargain model that fails twice.

Backup strategies deserve serious thought. Power loss is common during storms, exactly when you need pumping. Options include:

– Battery backup pumps with separate float switches and chargers

– Inverter systems sized to run the primary pump for limited cycles

– Water‑powered units where local water pressure and codes allow

Each path has tradeoffs. Battery units add runtime for hours; inverter setups can run the main pump briefly but need robust batteries; water‑powered units consume supply water and require vacuum breakers. Whichever you choose, test monthly and replace batteries on schedule. Pair backups with high‑water alarms for early warnings.

Local codes and good neighbor practices matter. Many jurisdictions prohibit discharge to sanitary sewers and may restrict storm connections without permits. Discharge water at least several feet from the foundation onto a surface that slopes away, and avoid directing flow across sidewalks or driveways where icing can occur. Use a dedicated, grounded, ground‑fault protected outlet for the pump. Where floodplains or high water tables are involved, check with local officials about backflow devices and discharge locations. If uncertain, a licensed contractor familiar with regional requirements can help you navigate approvals quickly.

Conclusion: A Dry Basement Without the Drama

Replacing a sump pump is less about horsepower hype and more about fit, planning, and care. Measure your head height and inflow, choose a quiet submersible or serviceable pedestal to match the space, and install with thoughtful touches like an air‑relief hole, reliable check valve, and a sealed cover. Keep a simple maintenance routine and add a backup that suits your risk and budget. With these steps, your system will hum along when storms shout, protecting your home without demanding attention.