Understanding the Importance of Conducting an Energy Audit

Outline

– Why energy audits matter and what they include

– How audits reveal inefficiencies in the envelope, HVAC, lighting, and plug loads

– Turning findings into practical energy savings with clear paybacks

– Sustainability benefits that go beyond lower bills

– Measuring results and building a culture of continuous improvement

Introduction: Energy touches every corner of a building’s life—comfort, productivity, maintenance, and long-term value. Yet most facilities operate on assumptions: “The boiler seems fine,” or “Those lights were upgraded years ago.” An energy audit replaces assumptions with evidence. It is a structured look at how a building actually performs, translating measurements into an action plan that balances efficiency, sustainability, and energy savings. Whether you manage a small home or a complex facility, the audit turns scattered symptoms—drafts, hot spots, noisy fans, rising bills—into a coherent diagnosis and treatment plan.

What an Energy Audit Is: Scope, Methods, and When to Do One

An energy audit is a systematic assessment of how a building uses and loses energy, and where practical improvements can be made. Think of it as a health check for your space: short observations when appropriate, deep diagnostics when the symptoms are stubborn, and a plan that ranks measures by cost and impact. At its core, the process gathers data on how the building envelope, heating and cooling systems, lighting, hot water, and plug loads behave day to day and season to season.

Audits generally fall into tiers with increasing rigor:

– Walk-through: Visual inspection, bill review, utility rate check, and simple recommendations.

– Diagnostic: Adds testing such as blower-door depressurization, duct leakage measurement, combustion analysis, and infrared scanning.

– Investment-grade: Detailed monitoring, modeling, cost estimating, and risk analysis to support funding decisions.

Common tools include thermal cameras that reveal hidden insulation gaps, pressure tests that quantify air leakage, data loggers that capture run-time patterns, and utility bill analytics that normalize for weather and occupancy. The deliverable is not just a list of fixes; it is a prioritized roadmap with estimated savings, costs, simple payback, and often lifecycle economics. Typical results for buildings that have not been tuned recently show potential reductions in energy use on the order of 10–30%, depending on climate, equipment age, and operational practices, though actual outcomes vary.

Timing matters. Audits are especially useful when bills trend upward without explanation, before major equipment replacements, after renovations, or ahead of budget cycles and sustainability reporting. Homes benefit from an audit before winter or summer peaks to catch envelope and HVAC issues. Commercial sites often align audits with planned shutdowns or off-hours to access equipment safely. Just as a map is most valuable before a journey, an energy audit is most effective when it guides what to fix first, what to monitor, and what to defer.

Finding Inefficiencies: Envelope, HVAC, Lighting, and Plug Loads

Inefficiency hides in plain sight. The envelope—the walls, roof, windows, and doors—acts like a sweater for your building; if it is full of holes, heat and coolth slip away. Air leaks around attic hatches, rim joists, and window frames can quietly drive heating loads, particularly in cold climates. Insulation that is compressed, wet, or uneven leaves thermal bridges that show up as cold streaks on infrared images. In many homes, uncontrolled infiltration can account for a notable share of heating energy, while in hot, humid regions, it can push up latent cooling loads and cause comfort complaints.

HVAC systems are the mechanical heart of the building, and their inefficiencies are often cumulative. Oversized equipment short-cycles and runs inefficiently; undersized ductwork elevates static pressure and fan energy; neglected filters increase resistance and reduce heat-transfer performance. Controls frequently drift: schedules stay in holiday mode; setpoints creep; economizers fail closed. In commercial settings, simultaneous heating and cooling in adjacent zones is a common red flag. In residences, a single-stage system serving mixed exposures can lead to rooms that are perpetually too warm or too cool.

Lighting and plug loads tell a different story. Lighting retrofits have become straightforward: high-efficacy lamps and fixtures typically use a fraction of the energy of older sources, and controls like occupancy and daylight sensors trim run-time. Plug loads—computers, chargers, appliances, entertainment electronics—often account for a steady baseline even when a building “sleeps.” Standby power alone can represent a meaningful slice of annual consumption in some households and small offices.

Audits surface patterns and hotspots:

– Envelope: attic bypasses, poorly sealed penetrations, missing insulation at eaves, and leaky windows and doors.

– HVAC: miscalibrated thermostats, nonfunctional economizers, excessive ventilation beyond code intent, and duct leakage in unconditioned spaces.

– Lighting: legacy lamps and fixtures with long hours of use, over-illuminated areas, and absent controls.

– Plug loads: always-on devices, servers and networking gear without power management, and shared spaces with unmanaged chargers.

The comparison between home and commercial buildings often comes down to scale and control. Homes see big wins from air sealing and targeted HVAC fixes; commercial spaces realize gains from controls tuning, ventilation right-sizing, and coordinated lighting strategies. In both cases, the audit’s value is clarity: it shows which changes matter most and why.

Turning Insights into Energy Savings: Measures, Costs, and Payback

Audit findings become tangible when translated into projects with timelines and budgets. The practical path starts with low-cost measures and operations tuning, then moves to moderate upgrades, and finally to capital improvements timed with equipment end-of-life. The goal is to maximize savings per dollar while maintaining comfort and reliability. A simple framework stacks the work so each step enables the next.

Low-cost and no-cost actions often deliver quick results: sealing obvious air leaks with appropriate materials, restoring HVAC schedules, calibrating sensors, adjusting outdoor air to match design intent, and adding smart power strips for office clusters or entertainment centers. In lighting, replacing legacy lamps in long-run areas and adding occupancy controls to restrooms, storage rooms, and corridors can shorten run-time dramatically. These measures typically offer short paybacks because they reduce waste without major purchases.

Moderate investments target building fundamentals. Air sealing performed methodically—attic plane first, then lower-level penetrations—can trim heating and cooling demand significantly. Upgrading attic insulation to recommended R-values and addressing duct leakage in unconditioned spaces further reduce loads. For HVAC, installing high-efficiency equipment when replacement is already planned, or adding variable-speed drives on eligible fans and pumps in commercial systems, can cut energy while smoothing operation. Water heating improvements, such as insulating hot-water pipes and setting appropriate temperatures, reduce both energy use and scald risk.

Capital upgrades require careful comparison of costs, savings, and non-energy benefits. Examples include comprehensive window replacements where envelope failures are severe, advanced heat-pump systems in appropriate climates, and integrated control platforms that coordinate HVAC, lighting, and ventilation. To compare options, auditors compile expected savings, maintenance impacts, and risk factors, then calculate simple payback (project cost divided by annual savings) alongside lifecycle metrics that consider service life and energy price scenarios.

Prioritization can follow clear rules of thumb:

– Start with load-reduction (seal and insulate), then right-size equipment.

– Fix controls and scheduling before replacing hardware.

– Bundle quick wins with longer-payback items to smooth cash flow.

– Time major upgrades with planned maintenance to reduce disruption.

Measured across many projects, achievable savings vary, but it is common for a well-executed package to deliver a notable reduction in energy use while improving comfort and reliability. The key is disciplined staging: eliminate waste, optimize operations, then invest where the numbers and the comfort story align.

Sustainability Beyond Bills: Carbon, Water, and Materials Synergies

Energy audits are often justified by bill savings, yet their impact on sustainability runs wider. Cutting energy reduces associated greenhouse gas emissions, which depend on your local electricity mix and any on-site fuels. When audits lower heating demand through air sealing and insulation, they reduce the need to burn fuel; when lighting and cooling loads fall, they reduce electricity consumption and its upstream impacts. Framed this way, each kilowatt-hour avoided and each therm saved represent not only money but avoided emissions and sometimes improved air quality within and around the building.

There are synergies beyond energy. Reduced internal heat gains from efficient lighting ease cooling loads and can permit smaller or less frequent compressor operation. Improved controls shift run-time away from peak hours, which often coincide with more carbon-intensive generation in some regions. Indoor environmental quality benefits, too: better ventilation balancing reduces drafts and noise; stable temperatures and humidity can help limit moisture issues, extending the life of finishes and furnishings.

Water use connects directly in surprising ways. Cooling systems, humidification, and domestic hot water all draw on water and energy together. By trimming loads through envelope and lighting improvements, you can reduce cooling tower cycles or hot water demand. Low-flow fixtures and heat-recovery strategies, where feasible, amplify this effect, turning an energy plan into a broader resource strategy.

Audits also guide material choices and waste reduction:

– Favor durable components with documented performance to reduce replacement frequency.

– Choose insulation and sealants suited to the climate and assembly to avoid rework.

– Plan deconstruction and recycling for replaced equipment and lamps.

– Consider refrigerant type and leakage control when selecting new HVAC systems.

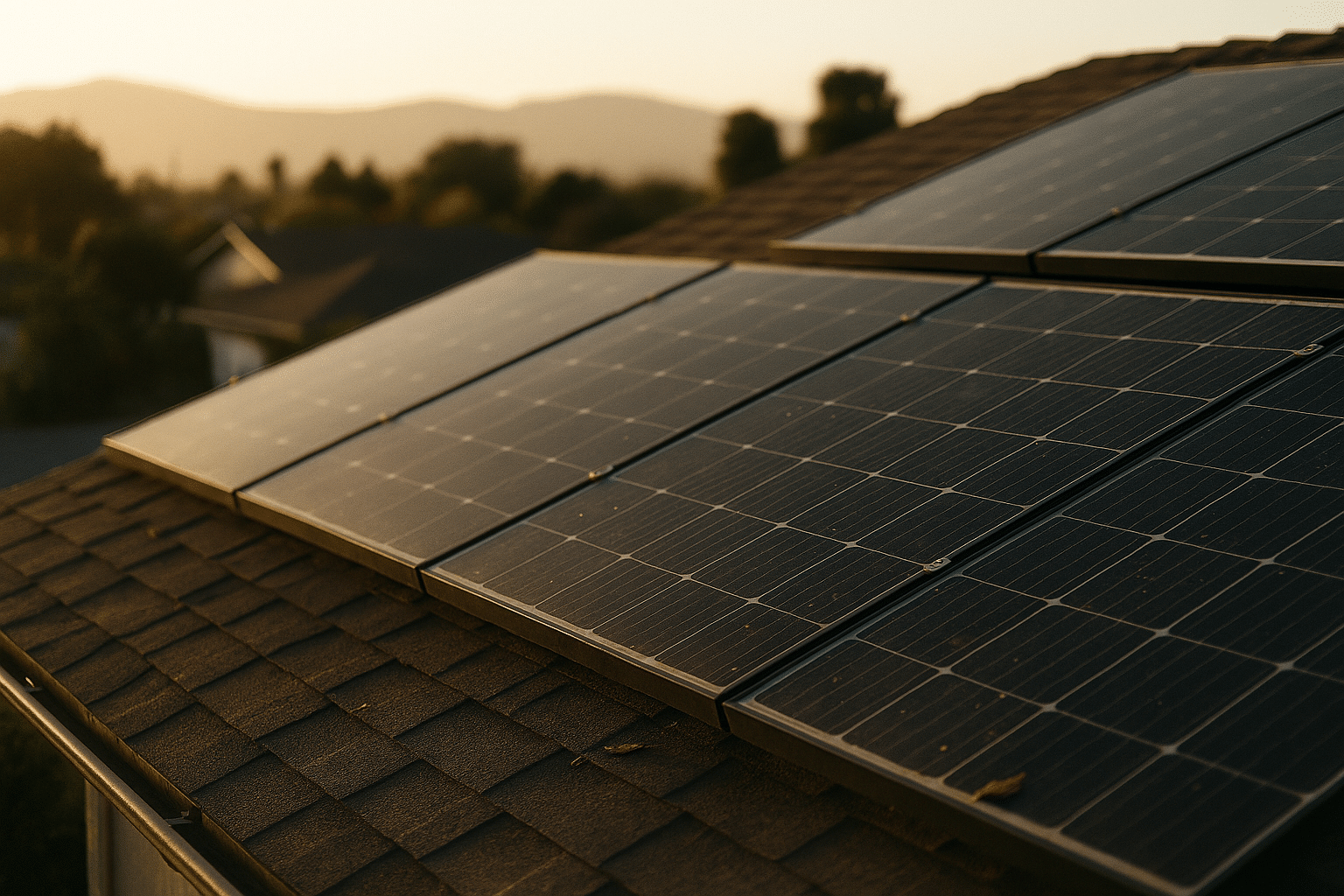

Resilience is a growing part of sustainability. Lower baseline loads mean a building can ride through outages more comfortably and make better use of backup power or future on-site generation. The audit clarifies which measures deliver both emissions reductions and resilience—tight envelopes, efficient equipment, and thoughtful controls that maintain safe conditions with less energy. In short, the sustainability story of an audit is a network of co-benefits that make spaces healthier, steadier, and easier on the planet.

Measurement, Verification, and Continuous Improvement

The story does not end when measures are installed. To ensure savings persist, you need measurement and verification—a light but disciplined process that compares post-project performance against a fair baseline. This involves gathering utility data, normalizing for weather and occupancy, and tracking key indicators such as energy use intensity, peak demand, and run-times. When possible, submetering or temporary data logging can separate HVAC, lighting, and plug loads, revealing whether each measure performs as intended.

A practical approach looks like this:

– Establish a baseline using at least a year of bills, noting anomalies and known schedule changes.

– Adjust the baseline for weather using heating and cooling degree days or similar metrics.

– Track post-project data monthly and seasonally; investigate deviations promptly.

– Document operational changes so savings are not misattributed.

Dashboards can help, but even a simple spreadsheet can surface trends. The aim is not perfection; it is learning. If savings fall short, the audit becomes a living document: revisit setpoints, check sensor calibration, confirm occupancy assumptions, and verify that measures were installed as specified. Sometimes the fix is as small as restoring a schedule that drifted during a holiday or resealing a gap opened by later maintenance.

Continuous improvement folds efficiency into daily routines. Maintenance teams keep a short list of high-impact checks for filters, dampers, and sensors. Occupants receive friendly cues about thermostat use, window operation, and device shutoff. Seasonal tune-ups ensure that economizers, heat pumps, and boilers operate as designed when the weather flips. Over time, a cadence emerges—measure, adjust, verify—that keeps energy performance aligned with comfort and mission.

Finally, plan for the next horizon. As equipment reaches end-of-life, the updated audit guides choices that lock in gains, like right-sizing replacements based on reduced loads or selecting controls that integrate easily. By treating measurement and verification as the closing chapter and the prologue, you maintain a trajectory where efficiency, sustainability, and energy savings reinforce one another year after year.