Understanding the Basics of EV Charger Installation

Outline and How to Use This Guide

Electric mobility is no longer a niche topic; it is moving from early adopters to the mainstream. With more than ten million electric vehicles sold annually worldwide in recent years, the everyday questions are shifting from “if” to “how” we charge. This guide offers a practical route through planning, installing, and operating EV charging at home, at work, and across shared or public spaces. You will find fundamentals, hands-on steps, and infrastructure insights presented in a clear sequence. Think of it as a map: you can read end to end, or jump directly to the section that matches your situation.

Here is the structure you can expect, along with what each part will help you accomplish:

– EV Charging Fundamentals: Understand power levels, charging curves, efficiency, and how long a charge truly takes in day-to-day use.

– Installation Planning: Learn how to assess electrical capacity, choose circuit ratings, prepare for permitting, and estimate costs responsibly.

– Infrastructure Beyond the Driveway: Explore building-wide and public charging, power management, payment, and site design that respects accessibility.

– Future-Proofing and Conclusion: Translate trends into practical choices you can make today without painting yourself into a corner.

Who is this for? Homeowners planning a garage upgrade, property managers adding chargers to multi-unit buildings, small businesses installing workplace charging, and fleet operators piloting depots. If you are comparing options for a single outlet, or sketching a plan for a dozen bays, the principles remain consistent: safety first, match capacity to demand, and allow room for growth. Along the way, we point to common rules of thumb, typical ranges for costs and timelines, and examples of how charging behavior varies based on commute length, climate, and daily routines. The goal is simple: give you enough depth to make informed decisions, without drowning you in jargon.

Before you dive deeper, consider two quick tips that often simplify the journey. First, focus on typical charging, not rare road-trip days—most energy flows at home or work, at modest power, overnight or during dwell time. Second, plan wiring and panel space for tomorrow’s needs even if you install a smaller unit today; copper in the wall is harder to change than a charger on the hook. With that, let’s turn to the core concepts.

EV Charging Fundamentals: Levels, Speeds, and Real-World Experience

Charging is fundamentally about moving energy from the grid into a battery at a rate your wiring and vehicle can accept. Three broad tiers cover nearly all situations. Level 1 uses a standard household outlet and delivers roughly 1–2 kW, adding around 5–10 km of range per hour for many cars, depending on efficiency. Level 2 steps up to dedicated circuits that commonly provide 7–11 kW in homes and small businesses, or up to 22 kW where three-phase power is available. DC fast charging jumps to 50–350 kW for rapid top-ups on road trips, subject to the vehicle’s limits and the station’s capability.

In daily life, what matters is not only peak power but also the charging curve. Batteries typically accept higher power at lower states of charge and taper as they approach full to protect cell longevity. This is why a 10–80% session on a fast charger may be significantly quicker per percentage point than the last 20%. For home or workplace charging, where time pressure is lower, Level 2 often balances speed, cost, and equipment complexity effectively. Efficiency also plays a role: onboard chargers and cables incur conversion and resistive losses, so wall-to-wheel efficiency commonly ranges around 85–95% depending on temperature and current.

Useful ballpark figures put time and energy in context:

– Typical compact to midsize EV battery: 50–80 kWh; larger vehicles can exceed 90 kWh.

– Typical consumption: 15–20 kWh per 100 km in mixed driving, higher in winter or at motorway speeds.

– Overnight Level 2 charge at 7.4 kW: adds roughly 50–60 kWh in 8 hours, enough for many drivers’ weekly needs.

– DC fast top-up: 20–30 minutes can provide substantial range, but availability and pricing vary by location.

Selecting a charging level starts with your use pattern. If you drive 30–60 km per day, Level 1 might keep pace when paired with consistent overnight charging, though it leaves little margin for unexpected trips. Level 2 creates that margin, replenishing a typical commute in under two hours and leaving time-based electricity tariffs to do their work. For road-trip flexibility, public fast charging fills the gap, while most energy across a year still tends to come from slower, routine sessions. Keeping this “right tool for the job” mindset makes planning simpler and more economical.

Installation Planning: Electrical Capacity, Safety, and Workflow

Successful installation begins with a site assessment that balances desired charging speed with the realities of your electrical service and budget. Start by identifying available panel capacity and the distance between the panel and mounting location. Longer runs and exterior routes add cost because of conduit, trenching, or wall penetrations. Many homes can support a new 32–40 A circuit for Level 2 charging without a service upgrade, while higher-power installations may require panel expansion or even utility-side changes. A licensed electrician can perform a load calculation to see what your panel can safely handle alongside ovens, HVAC, and other major loads.

Core safety elements should shape your plan:

– Dedicated circuit sized for continuous load (typically 125% of the charger’s continuous current).

– Proper overcurrent protection and ground-fault protection as required by local code.

– Correct wire gauge for the run length and ambient temperature; aluminum or copper conductors each have sizing rules.

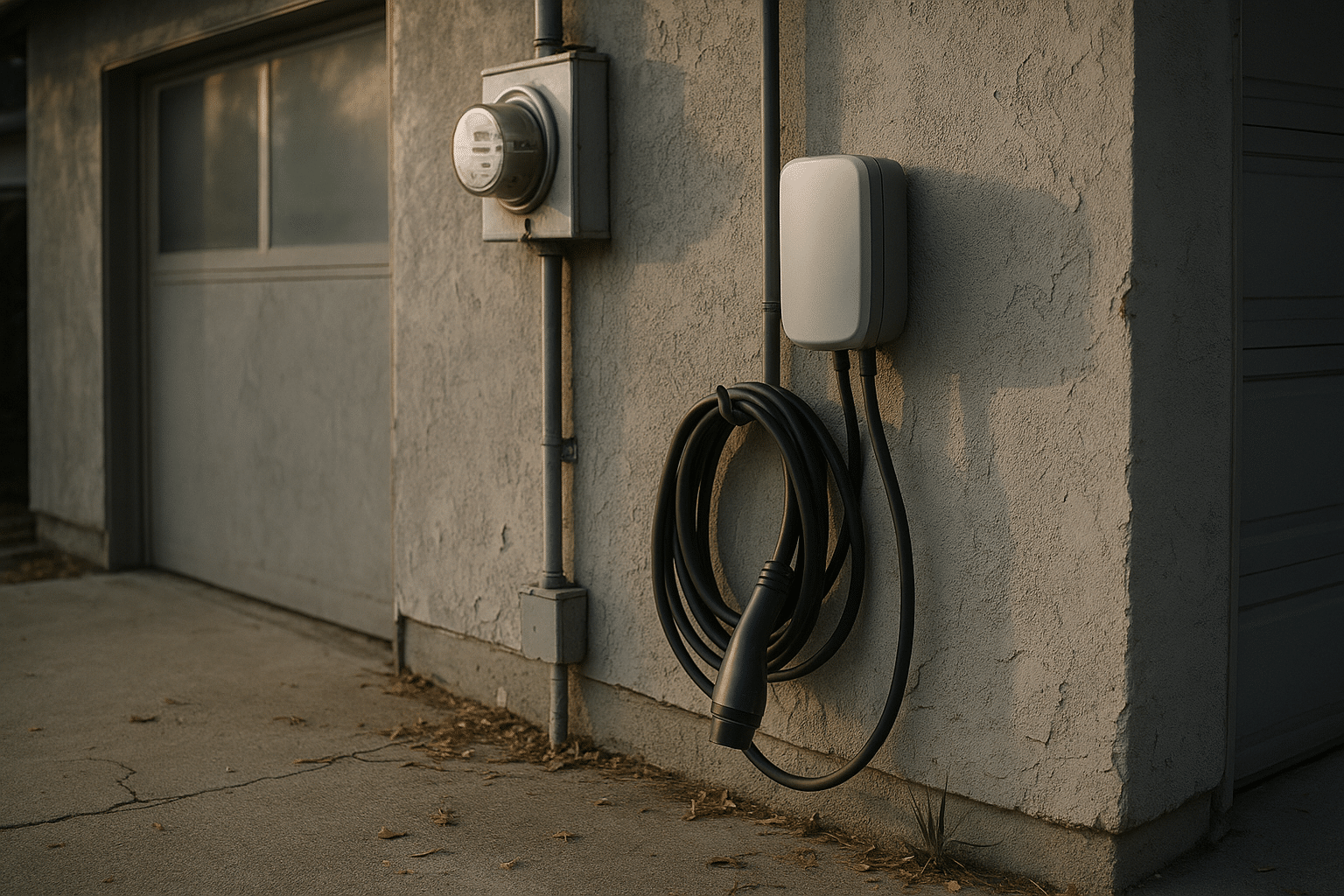

– Appropriate enclosure rating if mounted outdoors, with weatherproof fittings and thoughtful cable management.

– Clear labeling and a visible disconnect where required.

Permitting and inspection are not mere formalities—they protect people and property. Expect to provide a simple one-line diagram, equipment specifications, and sometimes proof of load calculations. Utility notification may be needed if you are increasing service or adding significant load. Budget ranges vary widely by region and site conditions, but a common pattern for a straightforward Level 2 install is equipment plus materials in the hundreds to low thousands of local currency, with labor from several hours to a full day. Panel upgrades, long conduit runs, or trenching to a detached garage can add substantially. It helps to request itemized quotes so you can see where the cost drivers sit.

A practical workflow keeps surprises to a minimum:

– Define your charging goal (e.g., 7.4 kW overnight) and cable reach to your parking spot.

– Verify panel capacity and breaker space; consider load management if space is tight.

– Obtain permits and schedule work with a licensed electrician familiar with EV charging.

– Install, test, and commission the unit; integrate any smart scheduling to align with off-peak rates.

– Keep documentation for warranty, inspections, and future upgrades.

Finally, think ahead. If you anticipate another EV or guests with plug-in cars, running a larger conduit or reserving breaker space now can be more cost-effective than opening walls later. Similarly, choosing a location that avoids trip hazards, respects parking movements, and shields the unit from constant spray or snow reduces maintenance. These simple, preventative choices turn a one-time project into a long-term asset.

Infrastructure Beyond the Driveway: Buildings, Fleets, and Public Networks

Once charging expands beyond a single home, the conversation shifts from one outlet to many ports, shared power, and user access. Multi-unit residences face the classic split-incentive problem: owners or tenants park in shared spaces, yet electrical rooms and billing live elsewhere. Common solutions include metered circuits per space, shared stations with access control, or a building-wide backbone that allows spots to be activated over time. The backbone approach—conduit, panel capacity, and network connectivity—can reduce future disruption, turning today’s few chargers into tomorrow’s many with minimal rework.

Load management is the quiet hero of scalable infrastructure. Rather than sizing for every port to run at full power simultaneously, smart systems allocate capacity based on who is plugged in and how urgently each vehicle needs energy. This can flatten peaks, lower demand charges where applicable, and fit more charging into limited service. Site design matters, too: stations near electrical rooms cut wiring costs, while pull-through layouts help vehicles with various charge-port locations. Where public access is intended, durable pedestals, clear wayfinding, and lighting improve usability and safety, while curb heights and cable reach should respect accessibility standards.

For workplaces and fleets, behavior data informs right-sizing. A depot where vehicles return daily can pair moderate-power charging with dwell-time scheduling, avoiding oversizing. In contrast, retail locations benefit from shorter, opportunistic sessions and visible placement that doubles as an amenity. Payment models vary by jurisdiction—per kWh, per minute, or session fees—but transparency is essential. Typical early-stage utilization can be in the single-digit percentage range, rising to 20–40% at mature, well-sited hubs; higher utilization rewards power-sharing and maintenance discipline.

Key considerations when scaling beyond a single charger include:

– Electrical capacity planning with room to expand (transformers, panels, and feeders).

– Open, standards-based communication for monitoring, access, and load control.

– Operations playbooks for uptime: routine checks, cable care, and swift fault resolution.

– Data-informed pricing that encourages turnover while covering costs.

– Inclusive design that accommodates varied parking sizes and mobility needs.

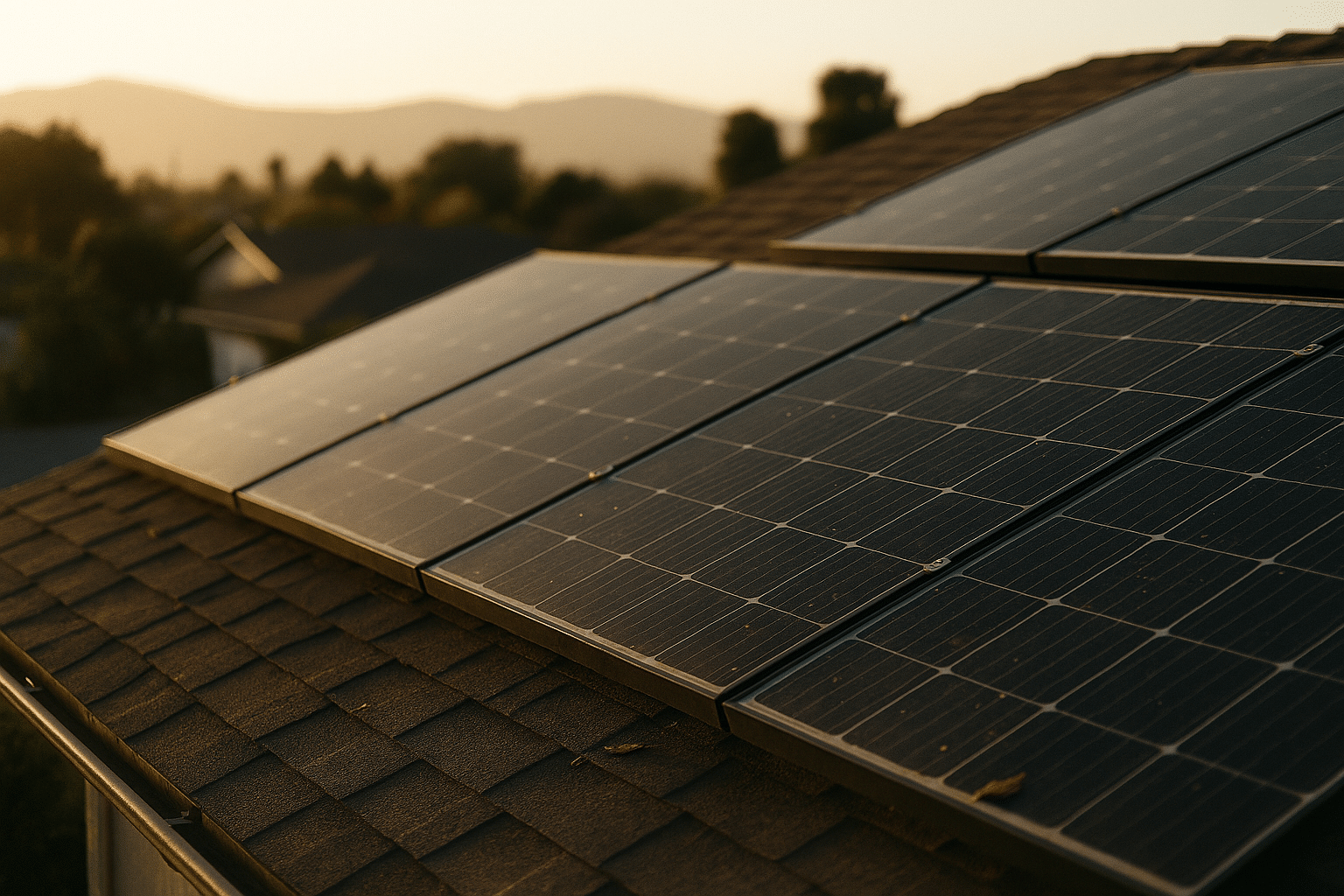

When done thoughtfully, infrastructure becomes resilient rather than brittle. It meets today’s drivers efficiently, anticipates tomorrow’s growth, and integrates with solar or on-site storage where feasible to soften grid impacts. The result is a charging network that quietly blends into the background of daily life—reliable, right-sized, and ready for the next wave of adoption.

Future-Proofing and Conclusion: What to Do Next

Future-proofing is about designing flexibility into wires, software, and habits. Battery chemistries are evolving, vehicle architectures are moving from 400 V to 800 V in some segments, and bi-directional charging is gaining attention for backup power and energy management. While you may not need every emerging feature today, it is practical to choose installations that can accept firmware updates, add ports, or adjust current dynamically. Conduit size, panel space, and cable routing are physical levers; open communication and scheduling are digital ones.

Consider a tiered approach to readiness:

– Build for your typical use case now (commute, fleet cycle, or customer dwell time).

– Reserve capacity in wiring and layout for the next charger or two.

– Adopt scheduling and load management early, even at small scale, to learn what works.

– Track incentives and rate structures; time-of-use or demand-responsive pricing can shift project economics.

– Document everything so future contractors understand what is in the walls.

Maintenance is the unsung component of reliability. Periodic checks for loose terminations, worn cable jackets, and water ingress prevent many failures. Software alerts that flag ground faults or unexpected downtime shorten repair cycles. Cleaning stalls, keeping bollards intact, and ensuring clear signage help drivers plug in confidently, which in turn sustains utilization and revenue for shared sites. If you are integrating solar or storage, prioritize safety coordination and clear labeling so emergency responders can identify disconnects quickly.

Bringing it all together, here is a simple action plan. Homeowners can start by estimating daily kilometers, confirming panel capacity, and getting two quotes for a Level 2 install that covers typical needs with headroom. Property managers can draft a phased backbone plan that aligns electrical upgrades with lease cycles. Fleet operators can pilot a few managed chargers, measure dwell patterns, and scale intentionally rather than all at once. Across all audiences, the goal is the same: make charging so dependable and ordinary that it fades into the background of your routine, like a well-placed light switch—always there, quietly doing its job, and ready for what’s next.